Issue: 01.07.2020

Page 18

Commissioning

Pre startup checks

Before starting the condensing unit, the following checks should be carried out as a minimum:

•

Check electrical supply is correct and all connections are sound.

•

All moving parts are free and guards fitted.

•

Compressor oil level satisfactory.

•

Initial settings for safety switches.

•

Overload set correctly.

•

All valves in correct operating position.

•

Initial refrigerant charge.

•

Gauge manifold connected to both low and high sides of system.

Running the unit

•

Run the unit and check compressor and condenser fan operation.

•

Check system pressures and temperatures, gas charge and running currents of motors to ensure correct

operation.

•

Check compressor suction superheat. This should be between 10K and 20K at normal operating conditions.

•

Final adjustment of safety switch settings.

•

Allow the system to run for 3

–

4 hours. Check compressor oil level and top up with the correct oil type as

required (RL32-3MAF). Recheck the compressor oil level again after 24 hours operation.

•

Carry out final leak test and ensure all panels/covers are fitted and screws tightened.

•

Log all information along with the system model and serial numbers for future reference.

•

Ensure that the customer / responsible person is provided with basic operating instructions and where

electrical isolators are situated in case of emergency.

Compressor operation

Scroll compressor motors are designed to run only in one direction.

This is not an issue with single phase

compressors as they will always run in the correct direction. The correct rotation of a three-phase compressor motor

depends on the connection of the three incoming phases to the unit. Correct rotation can be determined by a drop in

suction pressure and a rise in discharge pressure when the compressor is energized. Running the compressor for a

short period of time in reverse direction will have no negative impact but prolonged running in reverse direction may

cause premature failure.

To reverse the rotation of a three-phase scroll compressor, shut off the incoming power

supply to the unit, swap connection of any two of the three incoming phases at the unit isolator, reapply power to

the unit and following compressor restart, recheck operating pressures.

Do not operate scroll compressors in a vacuum condition, as this will cause the scrolls to overheat very quickly

causing premature failure.

Ensure an adequate liquid charge has been introduced to the high side of the system before starting to ensure a

minimum operating pressure on the suction side of 0.5 bar is maintained, otherwise overheating of the scrolls and

subsequent damage may occur.

Содержание Cellar Plus 70-S1

Страница 1: ...CELLAR PLUS CELLAR COOLER RANGE ISSUE 01 07 2020 CELLAR COOLER RANGE TECHNICAL MANUAL...

Страница 8: ...Issue 01 07 2020 Page 8 Installation Quick Guide Piping Single System Twin System...

Страница 24: ...Issue 01 07 2020 Page 24 Drawings Dimensional drawings Indoor Unit 80E...

Страница 25: ...Issue 01 07 2020 Page 25 Drawings Dimensional drawings Outdoor Units BSCU 30 M1 M3 BSCU 35 M1 M3...

Страница 26: ...Issue 01 07 2020 Page 26 Drawings Dimensional drawings Outdoor Units BSCU 40 M1 M3...

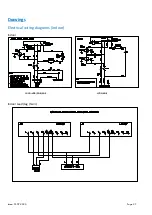

Страница 28: ...Issue 01 07 2020 Page 28 Drawings Electrical wiring diagrams Outdoor BSCU 30 M1 BSCU 35 M1 BSCU 40 M1...

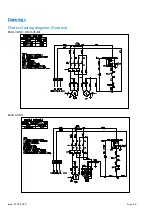

Страница 29: ...Issue 01 07 2020 Page 29 Drawings Electrical wiring diagrams Outdoor BSCU 30 M3 BSCU 35 M3 BSCU 40 M3...

Страница 33: ...Issue 01 07 2020 Page 33 Certification...

Страница 34: ...Issue 01 07 2020 Page 34 THIS PAGE IS LEFT BLANK INTENTIONALLY...