SET-UP 3

en-11

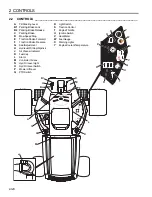

3.3

OPERATING CHECKS ______________________________________________________

After the initial inspection and installation of reels and

accessories test the mower and implements for proper

operation.

1. Test the Interlock System.

[Section 3.4 ].

2. Start mower and check that switches, pedals and

controls operate as described.

[Section 2.2 and 2.3]

3. Check that warning lights and alarm are working.

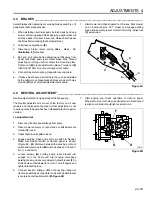

4. Check that brake pedal does not have more than one

inch free travel before engaging brake disc.

[Section

4.4]

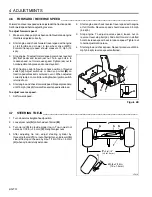

5. Operate traction pedal and check that mower operates

smoothly in both directions. Check that mower stops

when traction pedal is released. If necessary, adjust

forward and revese speeds.

[

Section 4.6]

6. Check that mower does not drift with engine running

and traction pedal in Neutral.

[Section 4.5]

7. Check adjustment of mow speed stop.

[Section 4.2]

8. Check operation of deck lift lever.

[Section 2.3]

9. Check operation of PTO switch.

[Section 2.3]

10. After operation, stop mower and inspect again for oil or

hydraulic leaks.

3.4

INTERLOCK SYSTEM ______________________________________________________

1.

The interlock system prevents the engine from starting

unless the parking brake is engaged, the traction pedal is

in neutral and the mower switch is OFF. The system also

stops the engine if the operator leaves the seat with the

mower switch ON, traction pedal out of Neutral, or parking

brake Disengaged.

2.

Perform each of the following tests to insure the interlock

system is functioning properly. Stop the test and have the

system inspected and repaired if any of the tests

fail

as

listed below:

l

the engine

does not

start in test 1;

l

the engine

does

start during tests 2, 3, or 4;

l

the engine

continues

to run during tests 5 or 6.

3.

Refer to the chart below for each test and follow the check

(

) marks across the chart. Shut engine off between each

test.

Test 1:

Represents normal starting procedure. The

operator is seated, parking brake is engaged, the

operator’s feet are off the pedals, and the mower

switch(es) is ‘OFF”. The engine should start.

Test 2:

The engine must not start if the mower switch is

“ON”.

Test 3:

The engine must not start if the parking brake is

“DISENGAGED”.

Test 4:

The engine must not start if the traction pedal is

pressed.

Test 5:

Start the engine in the normal manner then turn

mower switch “ON” and lift your weight off the seat.

+

Test 6:

Start the engine in the normal manner then

disengage parking brake and lift your weight off the seat.

+

+

Lift your weight off seat. The cutting units must stop rotating within seven (7) seconds.

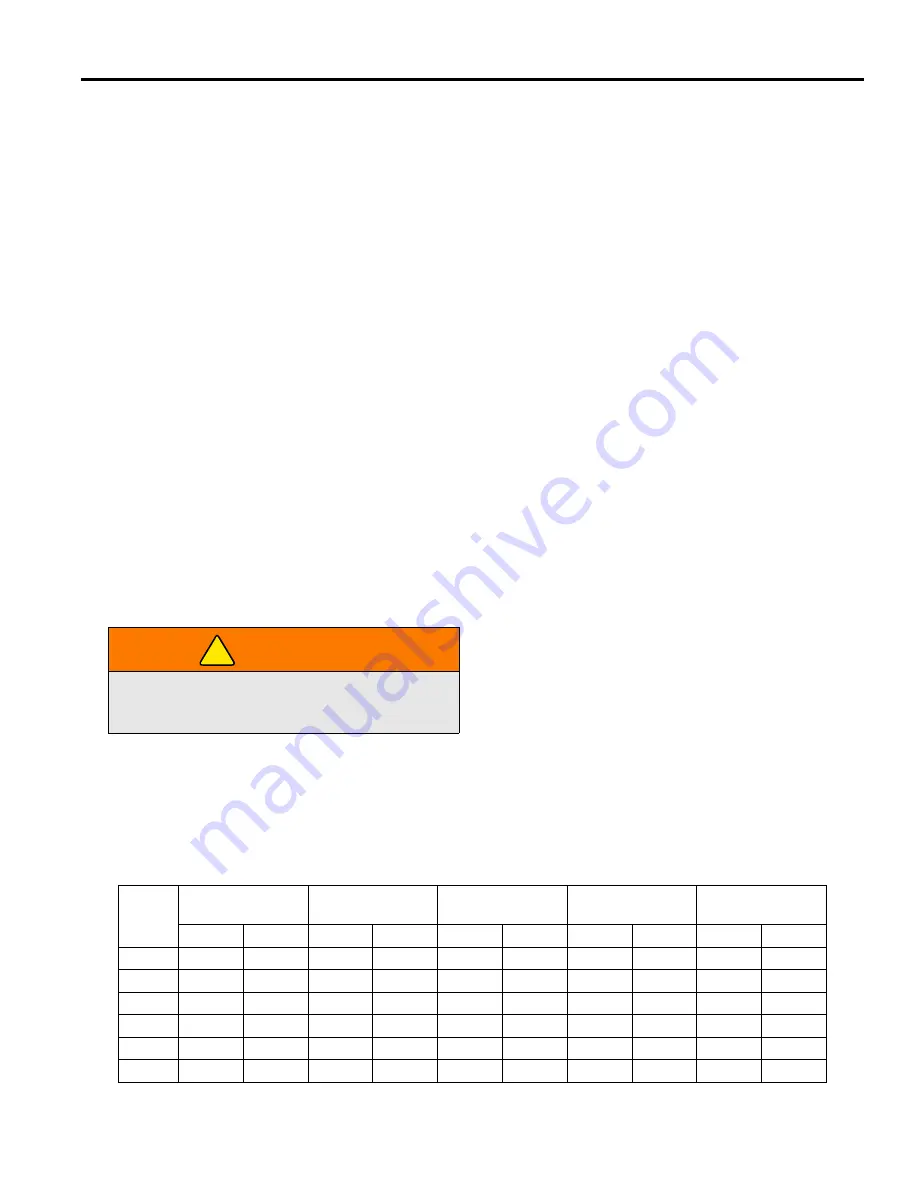

WARNING

Never operate equipment with the Interlock System

disconnected or malfunctioning. Do not disconnect or

bypass any switch.

!

Test

Operator

Seated

Parking

Brake

Traction Pedal

in Neutral

Mower

Switch

Engine

Starts

Yes

No

On

Off

Yes

No

On

Off

Yes No

1

2

3

4

5

+

+

6

+

+

Содержание AR-522 jossa ROPS

Страница 22: ...7 NOTES en 22 7 Notes...

Страница 23: ......

Страница 44: ...7 ANM RKNINGAR sv 22 7 ANM RKNINGAR...