M

AINTENANCE

8.2. Model for determining the actual use

The decisive factors for the type of operation are the

load spectrums with different cubic averages

k

.

The load spectrum indicates to what extent a driving

mechanism, or part of one, is subjected to its maxi-

mum stress or whether it is only subjected to lower

stresses. The cubic mean value (factor of the load

spectrum) is calculated using the following formula:

k

=

3

p

(

β

1

+

γ

)

3

·

t

1

+ (

β

2

+

γ

)

3

·

t

2

+

. . .

+

γ

3

·

t

∆

Darin bedeuten:

β

=

P ayload or ultimate load

Load capacity

γ

=

Dead load

Load capacity

k

=

Operating time with payload or partial load and dead load

T otal operating time

t

∆

=

Operating time with dead load

T otal operating time

The FEM 9.511 rule differentiates between four load

spectrums, which are identified by the definitions

and by the ranges of the cubic averages

k

. This

classification complies with ISO 4301/1.

The formula given for the cubic average

k

does not

take the weight of the harness into account. This is

permissible if the ratio

W eight of the harness

Load capacity

≤

0

,

05

To determine the mode of operation for calculating

the partial operating times (actual operating time),

the following load spectrum diagrams can also be

used.

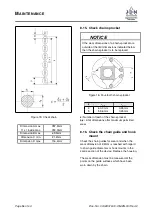

Figure 12: Diagram of the load spectrums

Load

spectrum

Definition

Cubic average

Collective load

factor

L1

(light)

Driving mechanisms or parts thereof, which are only subject

to the maximum stress in exceptional circumstances and are

only subject to very low stresses continuously.

k

≤

0

,

50

k

m

=

k

3

= 0

,

125

L2

(medium)

Driving mechanisms or parts thereof, which are subject to

the maximum stress fairly often and are only subject to low

stresses continuously.

0

,

50

< k

≤

0

,

63

k

m

=

k

3

= 0

,

25

L3

(heavy)

Driving mechanisms or parts thereof, which are often sub-

ject to the maximum stress and are continuously subject to

average stresses.

0

,

63

< k

≤

0

,

80

k

m

=

k

3

= 0

,

5

L4

(very heavy)

Driving mechanisms or parts thereof, which are regularly

subject to the maximum stress of adjacent stresses.

0

,

80

< k

≤

1

,

00

k

m

=

k

3

= 1

Page

42

of 64

Doc.-No.: VA049318-10-OM-EN-0319-64-2