I

NITIAL OPERATION

Check with nominal load

I

Alternatively switch your product

PROFI 25

TI

loaded with a nominal load to lifting and

lowering

If you release a control device, the chain must

come to a standstill in an acceptable time after

the brake has been applied. For physical reasons,

however, the braking distance cannot have the

value zero. The brake has a response time that is

dependent on the control length. A greater control

length increases this response time.

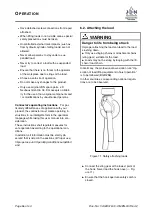

5.5.4. Check overload protection

WARNING

Danger due to overloading

If the overload protection is set too high, imper-

missibly high stresses may arise if a load exceed-

ing the permissible load capacity is attached.

I

Correctly set the overload protection

NOTICE

The overload protection must only be engaged

briefly in order to prevent unnecessary wear and

overheating of the drive.

Rules for running in hoist chains be-

fore carrying out the overload test

NOTICE

In case this information should not be observed

you damage the high tensile chain in your hoist

already during testing prior to initial use for which

the manufacturer does not undertake any liability.

Hoist chains must be run in prior to the overload

test, in order to ensure that the surface pressure at

the contact points of the chain links (in the joints)

can be withstood.

In preparation for overload testing, the following

pre-conditions must be fulfilled:

I

The joints of the chain must be thoroughly

lubricated. Observe the operation instructions.

I

The chain must be run in by raising and lower-

ing it five times with approximately 50% of the

nominal load capacity. This will increase the

load capacity of the joints sufficiently.

I

In particular, the section of the chain to be

tested with the excess load must be thor-

oughly lubricated once again.

Only then can the overload test be performed.

The testing of the overload protection is based on

the attachment of test loads.

1. Attach 125% of load capacity. If this load is

lifted, the overload protection setting must be

corrected.

Page

32

of 64

Doc.-No.: VA049318-10-OM-EN-0319-64-2