www.ittcontrols.com

13

Model 581A Differential Pressure Switch

Section 3

See

Figure 3.2, page 13.

c. Replace the bezel/lens assembly.

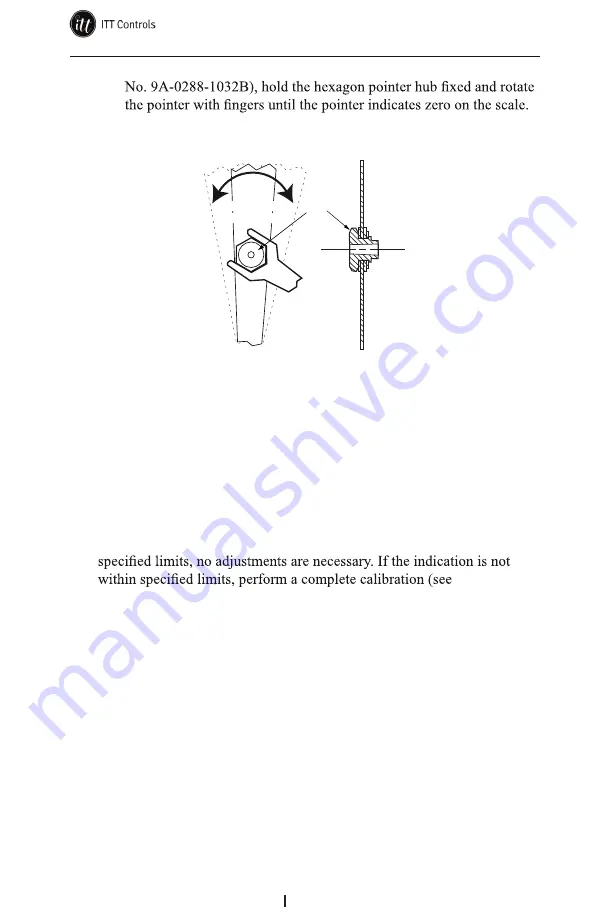

HUB

Pointer "slipped"

rotated on hub

Hub held in place

with 1/4" wrench

Figure 3.2—"Slipping" pointer

3. To test for reverse travel, connect the pressure source to the low-pressure

(LP) housing and vent the HP housing. Apply pressure to approximately

150% of the DP range. The pointer should move approximately 5% to

10% below zero.

4. To test for overtravel, connect the pressure source to the HP housing and

vent the LP housing. Apply pressure to approximately 150% of DP range.

The pointer should move approximately 5% to 10% above the full scale

mark.

5. Apply 0, 50, and 100% of full scale pressure. If the indication is within

Scale Plate

Installation and Removal, page 14

).

6. Make sure the instrument zero indication is correct; otherwise, repeat

step 2.

7. Verify the switch set points (refer to

Changing Switch Set Point, page 20

).

Pointer Installation and Removal

During adjustment and calibration of the unit, it may be necessary to remove

and reinstall the pointer. See the following procedures for instructions.

Pointer Installation

1. Position the pointer on the movement shaft with the pointer set at zero

scale. Obtain 75% to 90% pointer hub engagement on the movement

pinion shaft. The pinion shaft must not extend through the pointer hub.It

may be necessary to enlarge the hub hole using a tapered broach (includ-

ed in the calibration toolkit, Part No. 9A-0288-1032B).