IV.

PROGRAMMING

l

GENERAL

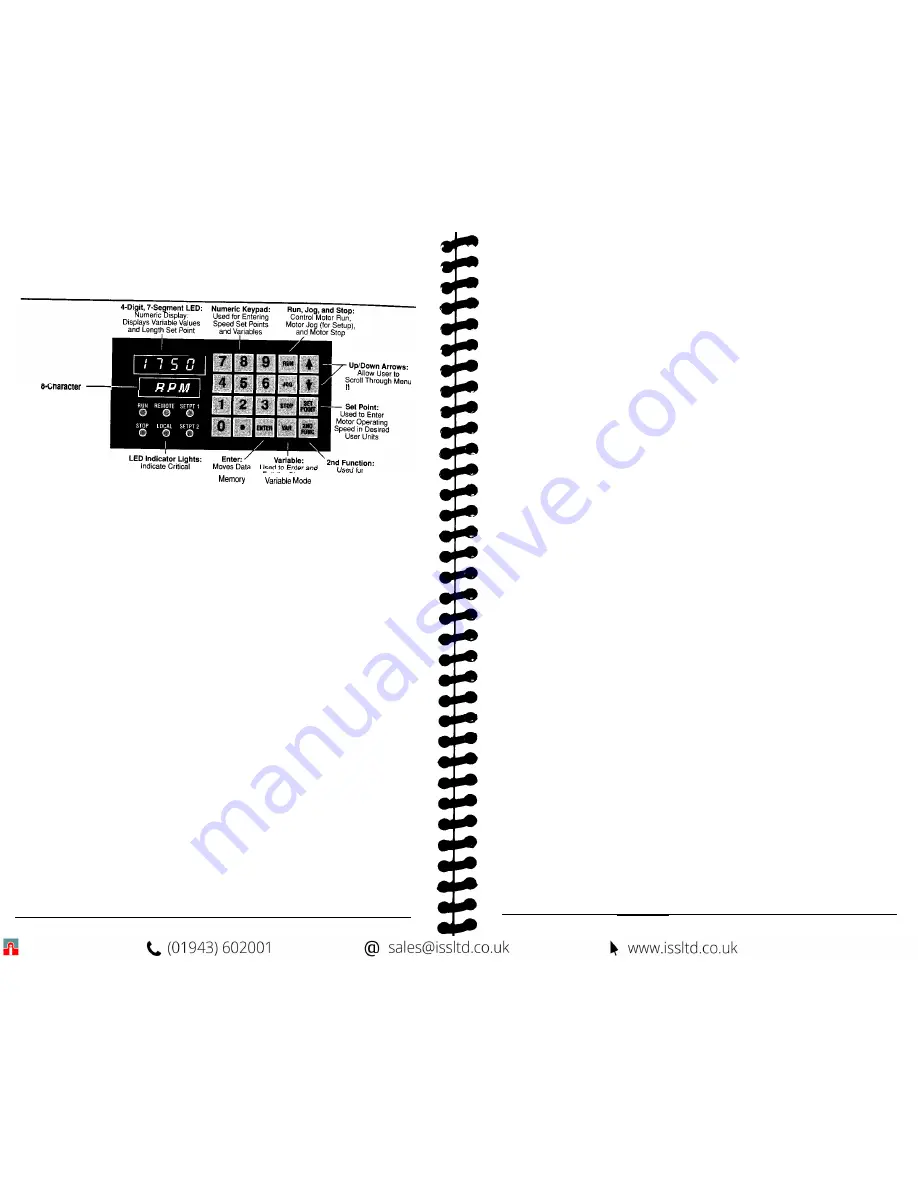

Alphanumeric Display:

Displays Current Operating

Mode or Identifies the Variable

Being Programmed

ems and Set Points

Operating Information Entries into Exit the

ENTERING AND ALTERING SET POINTS :

Change

Diagnostic Tests

Set Point - The

set

point can be adjusted to any speed (or ratio) by pressing SET

POINT,

entering a new speed using the number keys, and pressing

ENTER.

This

changes the programming of the current set point (Set Point 1,2,3,4 or Ratio 1,2,3,4).

The motor will immediately ramp to the new setting. If you wish to change a

non-selected set point, press

SET POINT,

then press the

UP

or

DOWN

arrows until the

desired set point is displayed, and enter the new set point.

Note: Decimal locations are fixed via programmable variables, and are not entered when

changing setpoints. The front panel LED displays will indicate which

set

poi

nt

is active.

SET POINT =

ACTIVE

LIGHTS ON SET POINT

1

1

2

2

1 & 2

3

NONE 4

Using the Arrow Keys to Alter Set Points

-

Minor adjustments to the set point

can be made by pressing the

UP

or

DOWN

arrows while the system is running. If an

UP or DOWN

arrow key is pressed, the active set point will increase or decrease. The

rate of this change will increase if the key is held.

Programming THE VARIABLES:

The MicroSpeed 196 is programmed by entering data into a menu of variables. Only the

variables that affect operation of the unit as it relates to the application must be

programmed. Upon power up, the MicroSpeed 196 will display

READY

on the alpha-

numeric display. This indicates that the MicroSpeed 196 is ready for operation or program-

ming. To program a variable, press

VAR

on the front panel keypad. The alphanumeric

display will prompt for a variable number, and the numeric display will indicate two

zeros (00), which will reflect the variable number entered. Enter the desired variable

number and press

ENTER

.

If you are unsure of the variable, the

UP and DOWN

arrows

on the keypad will allow you to scroll through the menu of variables. As you

9

scroll, the numeric display will indicate the number of the variable, and the alpha-

numeric display will name the variable. Press

ENTER

when the desired variable is

displayed.

When the variable to be programmed is accessed, enter data using the numeric keys, and

then press

ENTER.

Note: A decimalpointcannot lead an entry; the decimal placemust be preceded by a zero (0).

After

ENTER

is pressed, the display will ask for another variable number. If there is no

other variable data to be entered, press the

VAR

key to return to the

READY

mode.

List of Variables:

Reference Variables -

These variables tell the MicroSpeed 196 how to

control the motor, and can be changed in READY mode only:

01 Maximum RPM

02 User Units at Maximum RPM

03 Feedback Pulses per Revolution

04 Maximum Lead RPM (Follower)

05 Lead Pulses Per Revolution (Follower)

23 User Unity Ratio (Follower)

Operational Variables:

06 Jog Speed in User Units

07 Acceleration Time

08 Deceleration Time

10 User Unit Label

11 Keypad Lockout Selection

21 Display Selection

22 Follower Display Selection

29 Jog Ramp Selection

Control Loop Variables-

These variables tell the control how to correct for

speed errors:

09 Maximum Lead Wind-up (Follower)

12 Gain-P

13 Reset-l

14 Rate-D

Status and Alarm Outputs:

15 High Alarm

16 Low Alarm

17 Deviation Alarm (Follower)

18 Drive Enable

Auxiliary Mode Variables-

Allows for a third frequency, i.e., dancer

systems, to trim the Follower mode ratio:

24 Auxiliary Mode Selection

25 Auxiliary Reference Frequency

26 Auxiliary Gain Percentage

27 Auxiliary Trim Selection

28 Auxiliary Input Delay

10

Содержание MicroSpeed 196

Страница 1: ...MSMAN32C MicroSpeed 196...

Страница 19: ......