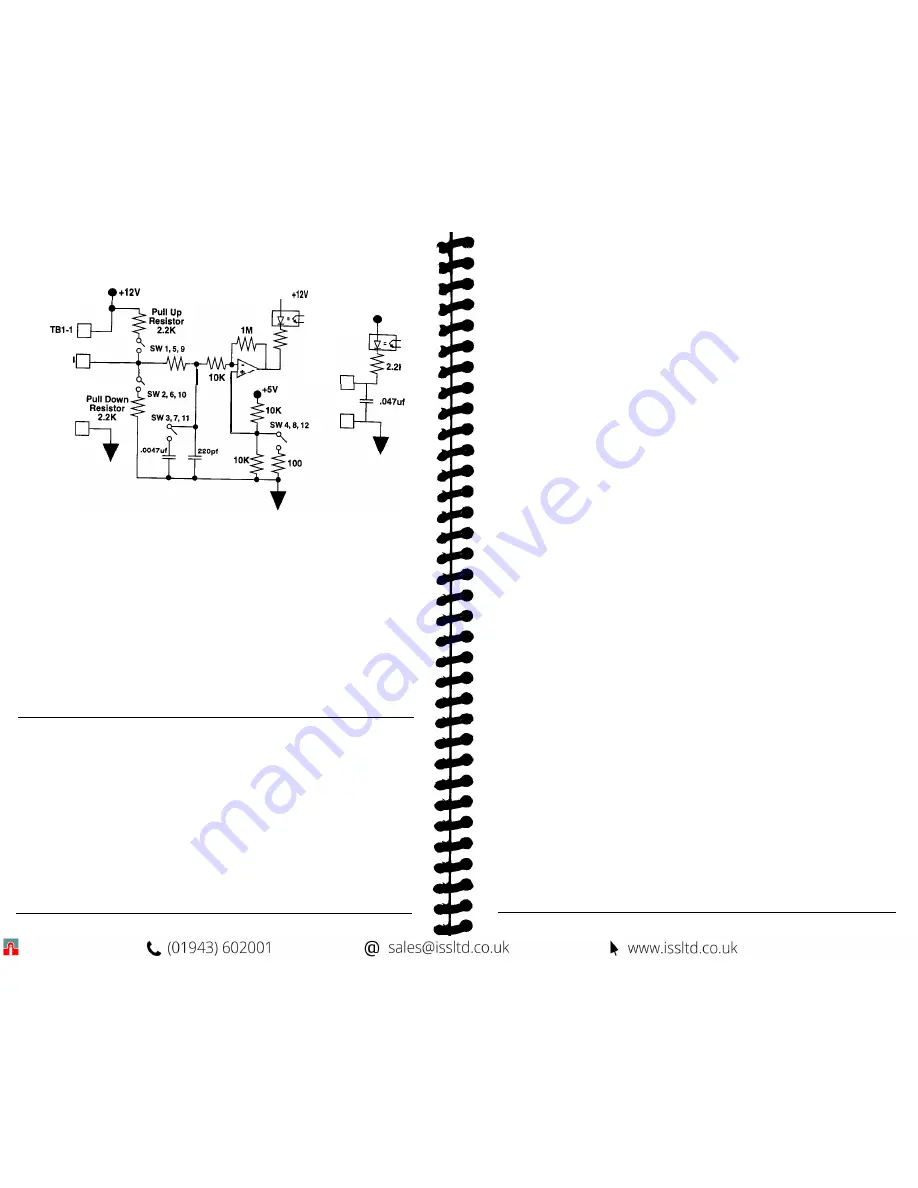

Diagram 4

Sensor Inputs, Switch Inputs:

Sensor Input

Switch Input

l

TB1-2,3,4

10K

TB1-5

+12V

2.2K

Sensor Connections -

The MicroSpeed 196 can accept: NPN Open Collecter,

3-wire (factory standard configuration); PNP Open Collecter, 3-wire; Magnetic pick-up,

2-wire; and Logic Level inputs. All sensors should have shielded cable with no unused

conductors.

The supply terminal (+12 Vdc unregulated) when using powered sensors (NPN or PNP)

for

Feedback, Lead,

or

Auxiliary

signals is terminal

TB1-1.

The common terminal for all sensor connections is terminal

TB1-5.

The

Feedback Signal

input is terminal

TB1-2.

The

Lead Signal

input is terminal

TB1-3.

The

Auxiliary Signal

input is terminal

TB1-4.

Note: When sharing signals, never use more than one pull-up resistor. See Diagram 4

for switch locations. See table below for sensor configurations.

Table 1

SENSOR SWITCH SETTINGS

Feedback Sensor

Lead Signal

12 11 10 9

Auxiliary Input

8 7 6 5 4 3 2 1

NPN Open Collector

OFF OFF OFF ON OFF OFF OFF ON OFF OFF OFF ON

PNP Open Collector

OFF OFF ON OFF

OFF OFF ON OFF OFF OFF ON OFF

Zero Crossing

ON ON ON

OFF

ON ON ON OFF ON ON ON OFF

Logic Level

OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF OFF

NPN Open Collector; 2.2K

pull-up to

+12v,

trigger point at

2.5V

PNP

Open Collector; 2.2K

pull-down to common, trigger point at 2.5V

Zero Crossing (Mag);

100mV minimum peak, trigger point at 50mV

Logic Level;

trigger point at 2.5V

5

EXTERNAL CONTROL INPUTS:

The external control inputs give the operator control over the operating parameters of

the MicroSpeed 196. These parameters include:

Master/Follower

modes;

Keypad

Lockout; Forward/Reverse

(positive or negative voltage output);

Closed/Open

Loop

modes; and Local/Remote.

Note: All external control inputs should be Sustained, Normally Open switches, or

hardwired.

Master/Follower

-

This input tells the MicroSpeed 196 to operate independently (as

a Master), or to follow the lead signal of another device (feedback from a lead motor

or a generated signal from a PLC). The MicroSpeed 196 only reads this input while

stopped in the Ready mode. Wiring of the

Master/Follower

input is as follows:

TB1-15 (Master/Follower)

to common (Open =

Master;

Closed =

Follower).

Keypad Lockout

-

This input disables selected entries from the front panel keypad of

the MicroSpeed 196, as defined by programming the

Keypad Lockout Selection

variable. Use of this function is highly recommended Wiring of the

Keypad

Lockout

input is as follows:

TB1-12 (Keypad Lockout)

to common (Open=Keypad

Avail

able; Closed=Key

pad Lockout).

Forward/Reverse

-

This controls the voltage polarity of the

Isolated Command

Output. Forward

is a positive voltage.

Reverse

is a negative voltage. The polarity

will change immediately when the switch is closed or opened. Wiring of the

Forward/

Reverse

input is as follows:

TB1-13 (Forward/Reverse)

to common (Open=

Forward;

Closed =

Reverse).

Closed/Open Loop

-

This enables or disables the PID control. In Open Loop mode,

the feedback is ignored, so control is extended to providing a particular command

output voltage only, with no correction to maintain a set point. Wiring of the

Closed/

Open

Loop

input is as follows:

TB1-18 (Closed/Open

LOOP)

to common

(Open =

Closed Loop,

Closed =

Open Loop).

Local/Remote

-

This input controls the point of information entry to the MicroSpeed

196. In Local mode, commands for all functions and programming are taken from the

front panel keypad and terminal strip. In Remote mode, all programming and speed

commands must come over the RS-422 link. (Refer to “Section XII, the

Serial

Communications”

for more information.) Wiring of the

Local/Remote

switch is as

follows:

TB1-10 (Local/Remote)

to common (Open=

Local;

Closed =

Remote).

SETPOINT CONTROL INPUTS:

There

are eight set points that can be programmed into memory (four master Speed Set

Points, and four follower Ratio Set Points). These eight set points allow the operator to

use different speeds upon start-up, and to alter speed by toggling from one set point to

another. The speed change will follow the ramp profile programmed for

Accel

and

Decel.

Two switches control which programmed set point is active. The two inputs are:

Set Point 3 & 4 Enable,

and

Set Point 1(3)/Set Point 2(4).

6

Содержание MicroSpeed 196

Страница 1: ...MSMAN32C MicroSpeed 196...

Страница 19: ......