4 Maintenance

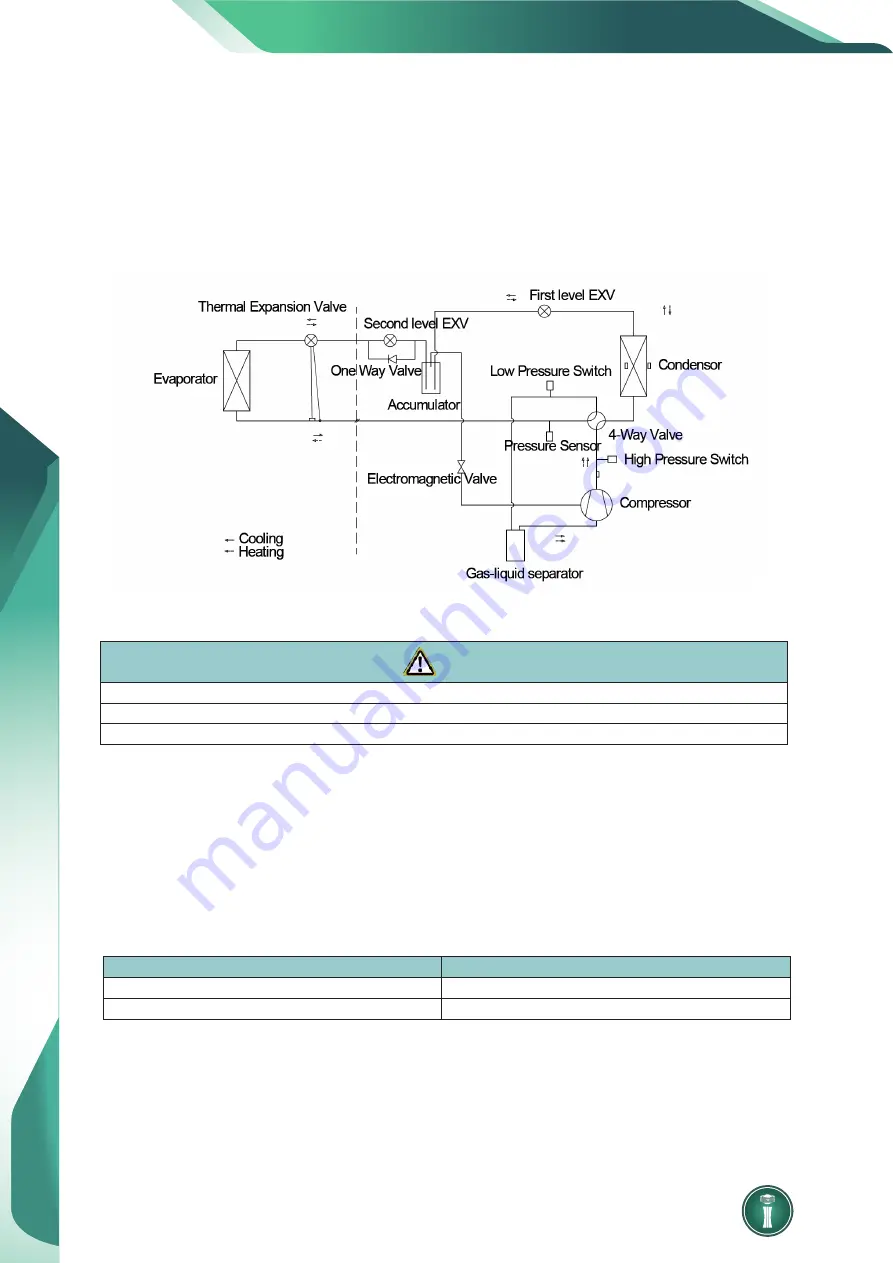

4.1 System Diagram

4.2 Connection Pipe Vacuum Pumping

NOTICE

①

Make sure the outlet of vacuum pump is away from fire source and is well-ventilated.

②

Before vacuum pumping, make sure the unit cut-off valves are closed.

③

When vacuum pumping, both the liquid pipe and the gas pipe must be pumped.

(1) Remove the caps of the liquid valve, gas valve and also the service port.

(2) meanwhile the gas and liquid valves should be kept closed in case of refrigerant leak.

(3) Connect the hose used for evacuation to the vacuum pump.

(4) Open the switch at the lower pressure side of the manifold valve assembly and start the vacuum pump.

Meanwhile, the switch at the high pressure side of the manifold valve assembly should be kept closed,

otherwise evacuation would fail.

(5) The evacuation duration depends on the unit’s capacity, generally.

Model

Time(min)

SEV2040H2R18

35

SEV4060H2R18

40

And verify if the pressure gauge at the low pressure side of the manifold valve assembly reads -0.1Mpa

(-750mmHg), if not, it indicates there is leak somewhere. Then, close the switch fully and then stop the vacuum

pump.

SERVICE MANUAL

55

Содержание Inverter FLEX24 DEV24H2R18

Страница 9: ...6 SERVICE MANUAL 2 Control 2 1 Operation Mode 2 1 1 Cooling Mode ...

Страница 10: ...2 1 2 Heating Mode SERVICE MANUAL 7 ...

Страница 18: ...Model SEV3060H2R18 3 1 2 Wiring Diagrams of IDUs Model DEV24H2R18 DEV36H2R18 SERVICE MANUAL 15 ...

Страница 19: ...Model DEV48H2R18 DEV60H2R18 16 SERVICE MANUAL ...

Страница 27: ...SEV2040H2R18 SEV4060H2R18 24 SERVICE MANUAL ...

Страница 30: ...Troubleshooting SERVICE MANUAL 27 ...