42

EIGER OPTIONAL FEATURES

STD

Low Ambient

- The low ambient kit is designed to protect the compressor when starting in

temperatures below 2° C. The temperature is measured at the air-end discharge. The temperature is

read using the standard Air-end temperature sensor. When the Low ambient option is installed and

selected and the A/E Discharge Temperature is measured to be below 2°C, the compressor will be

started when commanded but will delay to load a period of time defined by the Low Ambient Delay

Time, Section 12. This will allow the coolant temperature to rise above an allowable level before

loading the compressor in cold environments. When the Low ambient option is not installed the

machine will not start if the A/E Discharge Temperature is below 2°C. The machine will trip on a Low

ambient fault. This trip will be logged in the fault table. The user can re-start the compressor by

holding the start button in for 10 seconds. Each time the compressor faults on a Low Ambient trip the

customer will have to manually restart and the trip will be recorded in the fault table.

STD

Power Out Restart

- At loss of power to the machine, a software or hardware flag is set

indicating the operational status of the compressor. Once power returns, the flag is evaluated and the

compressor is returned to its previous operational state. PORO when enabled will be active in all

Local and Remote control modes of the compressor. For PORO to execute, the PORO option must

be installed and the PORO enable must be set to ON in the factory set-up menu. The customer then

has visibility to turn off/on and set the time delay of the PORO option in the advanced set-up menu.

Assuming this is the case, if power is lost to the compressor while the unit is running or is stopped in

auto start/stop, the control will store in memory the current operating conditions.

When power returns to the unit, the control will first verify the PORO option is installed, enabled and

turned ON. Next the control will check to see if the unit was running or stopped in auto start/stop

when power was lost. If it is determined this was the case, it will start the PORO sequence. The

control will energize the PORO horn and start a count down on the display. The RED light will flash

indicating a Warning condition and the horn will blow for the number of seconds (see table 12) the

operator set in the PORO time set point. At the end of the count down the horn will stop blowing and

the compressor will start. The PORO count down can be stopped at anytime by pressing the Stop /

Reset button on the user interface. Pressing any button will cause the horn to stop blowing and the

count down to stop. The control will power up normally in a ready to start mode. If unit is being

operated using remote control, the compressor will not automatically restart after power returns if

PORO kit is not installed.

ENH

Scheduled Start / Stop

- This is an auto start / stop mode of operation based on the Real

Time Clock current time. A Scheduled Start Time set point is used to automatically start the

compressor when the current time equals the Scheduled Start Time entered for the set point. A

scheduled Stop Time set point is used to automatically stop the compressor when the current time

equals the Scheduled Stop time entered for the set point. This mode of operation can be turned on

and off by selecting the desired mode in the Scheduled Start Stop

On/Off Set point, When Scheduled Start/Stop is turned on and the current time equals the Scheduled

Start Time set point, and the compressor is

not currently running, the compressor will automatically activate the output for the PORO horn for 10

seconds (hard coded) to warn anyone in the surrounding area that the compressor is about to start.

The UI will display a Warning message “Scheduled Start in X seconds”. X is a countdown from 10 to

0 seconds. After 10 seconds the compressor will automatically start as long as the compressor is not

in a Fault condition or manually stopped by pressing the Stop / Reset button. When Scheduled

Start/Stop is turned on, and the current time equals the Scheduled Stop Time set point, and the

compressor is currently running, the compressor will automatically stop. The compressor can

Содержание R110IU-10

Страница 5: ...5 S3 Intellisys Controller Operating Instructions...

Страница 6: ...6 Software Navigation...

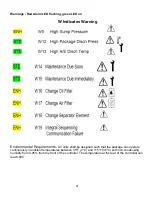

Страница 7: ...7 Eiger Controller Fault Indicators 020 Tr Motor PTC Open High Motor Temperature...

Страница 14: ...14 Star Delta Wiring Diagram...

Страница 15: ...15...

Страница 16: ...16 Soft Start Wiring Diagram...

Страница 17: ...17...

Страница 18: ...18 Line Start Schematic...

Страница 19: ...19...

Страница 20: ...20 Process and Instrumentation Diagram...

Страница 21: ...21...

Страница 28: ...28 Maintenance...

Страница 29: ...29 Maintenance...

Страница 30: ...30 Maintenance...

Страница 31: ...31 S3 Controller Input Output Overview AI Analog Input DI Digital Input DO Digital Output...

Страница 45: ...45 Standard S3 Menu Structure and Parameters Table 12...

Страница 46: ...46 Standard S3 Menu Structure and Parameters Table 12...

Страница 47: ...47 Standard S3 Menu Structure and Parameters Table 12...

Страница 49: ...49 Modbus Register Listing...

Страница 50: ...50 Table 13 Modbus Register Listing...

Страница 52: ...52 Appendix 1 Thermistor 2ATT 34 to 124 C 255 F Air end Discharge...

Страница 53: ...53...

Страница 54: ...54...

Страница 55: ...55...

Страница 56: ...56...

Страница 57: ...57...

Страница 58: ...58 General Specifications for Eiger Packages...

Страница 59: ...59...

Страница 60: ...60...

Страница 61: ...61...

Страница 62: ...62...

Страница 63: ...63...

Страница 64: ...64...

Страница 65: ...65...

Страница 66: ...66...

Страница 67: ...67...

Страница 68: ...68...

Страница 69: ...69...

Страница 70: ...70...

Страница 71: ...71...

Страница 72: ...72...

Страница 73: ...73...

Страница 74: ...74...

Страница 75: ...75...

Страница 76: ...76...

Страница 77: ...77...

Страница 78: ...78...

Страница 79: ...79...