22

GENERAL OVERVIEW OF THE COMPRESSOR

The compressor is an electric motor driven, single stage screw compressor, complete with

accessories piped, wired and base plate mounted. It is a totally self contained air compressor

package. The standard compressor is designed to operate in an ambient range of 2_C to 46_C (35_F

to 115_F). The standard maximum temperature of 46_C (115_F) is applicable up to an elevation of

1000m (3280ft) above sea level. Above this altitude significant reductions in ambient temperature are

required if a standard motor is to be used. Compression in the screw type air compressor is created

by the meshing of two (male & female) helical rotors.

The air/coolant mixture discharges from the compressor into the separation system. This system

removes all but a few PPM of the coolant from the discharge air. The coolant is returned to the

cooling system and the air passes to the after cooler and out of the compressor through the moisture

separator (optional).

Air is pulled into the machine by the cooling fan and is pushed through the combined cooler / after

cooler. By cooling the discharge air and passing it through the separator, much of the water vapor

which is naturally present in the air, can be removed.

The coolant system consists of a sump, cooler, thermostatic valve and a filter. When the unit is

operating, the coolant is pressurized and forced to the compressor bearings. The compressor load

control system is automatic ’On

−

Off line’. This is accomplished by the Intellisys S3 Controller

monitoring the discharge pressure and operating the SV1 solenoid valve. When the load valve is on

(Loading) the blow down solenoid valve SV3 is off and this logic reverses when the unit unloads. The

compressor will operate to maintain a set discharge line pressure and is provided with an auto restart

system for use in plants where the air demand varies widely. Panel instrumentation is provided to

indicate the compressor operating conditions and general status.

CAUTION

LOW DEMAND APPLICATIONS

During periods of low demand, the compressor may not reach its normal operating

temperature. Sustained operation at low demand can result in the build up of condensate in

the coolant. If this situation occurs, the lubricating characteristics of the coolant can be

impaired which may lead to damage of the compressor.

THE COMPRESSOR SHOULD BE ALLOWED AMPLE LOADED RUNNING TIME

.

Содержание R110IU-10

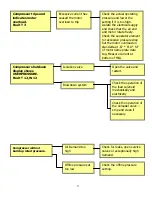

Страница 5: ...5 S3 Intellisys Controller Operating Instructions...

Страница 6: ...6 Software Navigation...

Страница 7: ...7 Eiger Controller Fault Indicators 020 Tr Motor PTC Open High Motor Temperature...

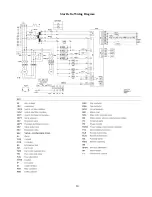

Страница 14: ...14 Star Delta Wiring Diagram...

Страница 15: ...15...

Страница 16: ...16 Soft Start Wiring Diagram...

Страница 17: ...17...

Страница 18: ...18 Line Start Schematic...

Страница 19: ...19...

Страница 20: ...20 Process and Instrumentation Diagram...

Страница 21: ...21...

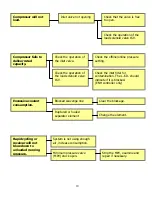

Страница 28: ...28 Maintenance...

Страница 29: ...29 Maintenance...

Страница 30: ...30 Maintenance...

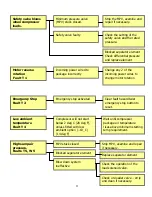

Страница 31: ...31 S3 Controller Input Output Overview AI Analog Input DI Digital Input DO Digital Output...

Страница 45: ...45 Standard S3 Menu Structure and Parameters Table 12...

Страница 46: ...46 Standard S3 Menu Structure and Parameters Table 12...

Страница 47: ...47 Standard S3 Menu Structure and Parameters Table 12...

Страница 49: ...49 Modbus Register Listing...

Страница 50: ...50 Table 13 Modbus Register Listing...

Страница 52: ...52 Appendix 1 Thermistor 2ATT 34 to 124 C 255 F Air end Discharge...

Страница 53: ...53...

Страница 54: ...54...

Страница 55: ...55...

Страница 56: ...56...

Страница 57: ...57...

Страница 58: ...58 General Specifications for Eiger Packages...

Страница 59: ...59...

Страница 60: ...60...

Страница 61: ...61...

Страница 62: ...62...

Страница 63: ...63...

Страница 64: ...64...

Страница 65: ...65...

Страница 66: ...66...

Страница 67: ...67...

Страница 68: ...68...

Страница 69: ...69...

Страница 70: ...70...

Страница 71: ...71...

Страница 72: ...72...

Страница 73: ...73...

Страница 74: ...74...

Страница 75: ...75...

Страница 76: ...76...

Страница 77: ...77...

Страница 78: ...78...

Страница 79: ...79...