26

1.6

Intellisys

S3

Serial Communications

- RS-485, 500 to 1000 Meters

Port Description Control Term

ENH

Port #1 Integral Sequencing, X4I, X8I X07 1-2

CMC Multi-485, Serial Programming

ENH

Port #2 Remote Monitor / Control, X08 1-2

Modbus RTU

STD

Port#2 Modbus Read Only X08 1-2

Serial Communications Comments

ENH

Serial Port #1 - S1 Integral Sequencing, X4I, X8I, Hardware - RS485, 2 Wire Half Duplex,

Opto-isolated, and capable for communicating up to 4000 ft from a host device. Software - CMC

Multi-485.

ENH

Serial Port #2 - IEO, ASC, Remote Monitoring and control of the compressor. Hardware -

RS485, 2 Wire Half Duplex, Opto-isolated,and capable for communicating up to 4000 ft from a host

device. Software - Modbus Slave, RTU, Selectable Baud Rate, 2 Stop bits, 8 Data bits, No Parity.

Modbus Baud Rate - Selectable from any one of the following standard Baud rates. 1200, 2400,

4800,9600, 19200, 38400, 57600, 76800, 115200.

Modbus Registers - See Paragraph 13 “Modbus Register Listing” for the compete register listing

with detailed descriptions. Modbus Commands Supported - At a minimum Modbus 03 Read Holding

Register, and 06 Preset Single Register.

This serial port must be capable of connecting to a multi-drop, RS485 network with up to 32

devices functioning as a Modbus Slave only. This serial port will be exposed to all Modbus network

traffic intended for any device on the network. Serial communication handling must not hinder safe

and timely machine control. The serial port should be capable of servicing communications at least

twice per second. Any serial communications intended for this slave device must be responded to

within 500 milliseconds.

ENH

Serial Control

- Starting the compressor using serial communications can be accomplished

only if RC, Remote Control, is set to Modbus control. See Section12

For Modbus control commands to operate, the Status Register (1) bit 0 must be set High for all

Status Register write commands to enable and maintain Host control. To remain in Host control

mode, serial communications (any serial communication) must be maintained with a maximum of 2

seconds between communications. If for any reason serial communications is lost (not accessed

within 2 seconds), the compressor reverts to Local control and continues to run using the local set

points.

The compressor is started by placing the compressor in Host Control, Status Register 1, bit 0 to a

1 (Host), and bit 1 to a 1 (Run) or a Hex 03 command. This will start the compressor and place it in a

run condition. If the pressure is such that the compressor needs to run (depending on the mode of

operation) the compressor will start and run until the compressor no longer needs to run to maintain

pressure. When the compressor is in a run mode, but no longer needed to make air, the compressor

motor will be stopped in “Auto Restart” but will restart any time air is needed. Local Control stopping

should always remain active and of the highest priority for safety of the compressor. If the compressor

is stopped locally, all remote control operation is cancelled The Units of Measure for the Pressures

read serially will always be read in PSI and temperatures in Deg F.

Содержание R110IU-10

Страница 5: ...5 S3 Intellisys Controller Operating Instructions...

Страница 6: ...6 Software Navigation...

Страница 7: ...7 Eiger Controller Fault Indicators 020 Tr Motor PTC Open High Motor Temperature...

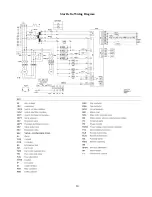

Страница 14: ...14 Star Delta Wiring Diagram...

Страница 15: ...15...

Страница 16: ...16 Soft Start Wiring Diagram...

Страница 17: ...17...

Страница 18: ...18 Line Start Schematic...

Страница 19: ...19...

Страница 20: ...20 Process and Instrumentation Diagram...

Страница 21: ...21...

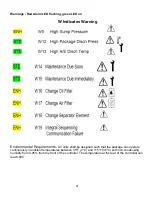

Страница 28: ...28 Maintenance...

Страница 29: ...29 Maintenance...

Страница 30: ...30 Maintenance...

Страница 31: ...31 S3 Controller Input Output Overview AI Analog Input DI Digital Input DO Digital Output...

Страница 45: ...45 Standard S3 Menu Structure and Parameters Table 12...

Страница 46: ...46 Standard S3 Menu Structure and Parameters Table 12...

Страница 47: ...47 Standard S3 Menu Structure and Parameters Table 12...

Страница 49: ...49 Modbus Register Listing...

Страница 50: ...50 Table 13 Modbus Register Listing...

Страница 52: ...52 Appendix 1 Thermistor 2ATT 34 to 124 C 255 F Air end Discharge...

Страница 53: ...53...

Страница 54: ...54...

Страница 55: ...55...

Страница 56: ...56...

Страница 57: ...57...

Страница 58: ...58 General Specifications for Eiger Packages...

Страница 59: ...59...

Страница 60: ...60...

Страница 61: ...61...

Страница 62: ...62...

Страница 63: ...63...

Страница 64: ...64...

Страница 65: ...65...

Страница 66: ...66...

Страница 67: ...67...

Страница 68: ...68...

Страница 69: ...69...

Страница 70: ...70...

Страница 71: ...71...

Страница 72: ...72...

Страница 73: ...73...

Страница 74: ...74...

Страница 75: ...75...

Страница 76: ...76...

Страница 77: ...77...

Страница 78: ...78...

Страница 79: ...79...