The motor in the compressor module unit can operate

continuously at 200°F and intermittently at 221°F.

However, as previously stated it is desirable to limit the oil

temperature to no more than 175°F. This will enhance the

life of the hydraulic system, and less speed drop-off will

occur at high ambient temperature.

Some speed decrease at higher temperatures is normal

due to reduced volumetric efficiency of the pump and

motor as they handle lower viscosity oil. Using higher

viscosity grades of hydraulic oil for high ambient operation

can minimize this.

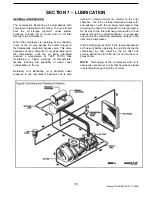

Hydraulic Reservoir

Hydraulic reservoir for the compressor alone should be in

the 30-40 gallon size range at a minimum, and larger if

space and weight considerations allow. If other motors

feed simultaneously from the same tank, it should be sized

proportionately larger to handle the additional flow. Follow

established design practice for tank layout. Inlet and outlet

connections should be well separated, and tank should be

baffled. It is desirable that an outlet strainer be fitted. A cut

off valve for service should be included, along with a clean

out port. Tank must be vented to atmosphere and should

include adequate expansion volume.

Hydraulic Filtration

In addition to a tank strainer, a hydraulic filter must be

fitted either in the return line or in the pressure line. We

highly recommend pressure side filtration to better protect

the motor and spool-type diverter valve (both of which

have close tolerance parts) from any particles that get

through the tank strainer or a regenerated in the pump.

Filter should have a nominal rating of 5-10 micron.

Specifically, Absolute Rating per ISO 16889 (new) should

be 5-10 for Bx(c)>200. Flow rating should be for a

minimum of 30GPM.Connectthefilter inline with the

pressure line going to the hydraulic oil inlet of the

compressor.

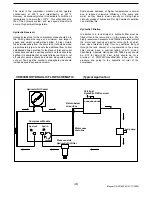

VHP90CMH HYDRAULIC FLOW SCHEMATIC

Compressor Module

Hydraulic Oil Cooler

hyd out

hyd in

hyd pump

uuuuuuuuuuuu

Return below

oil surface

Motor case

drain line

Pressure-side

Hydraulic Oil Filter

30-40 gal

Hydraulic Oil Reservoir

motor

(Typical Application)

(

22

)

Manual P/N 22189203 (01/17/2005)

Содержание HP60CMH

Страница 6: ... 6 Manual P N 22189203 01 17 2005 ...

Страница 7: ... 7 Manual P N 22189203 01 17 2005 ...

Страница 8: ... 8 Manual P N 22189203 01 17 2005 ...

Страница 9: ... 9 Manual P N 22189203 01 17 2005 9 Manual P N 22189203 01 17 2005 ...

Страница 10: ... 10 Manual P N 22189203 01 17 2005 10 Manual P N 22189203 01 17 2005 ...

Страница 41: ... 41 Manual P N 22189203 01 17 2005 ...

Страница 42: ...22147409 90CFM Cooler Assembly 22489389 60CFM Cooler Assembly 42 Manual P N 22189203 01 17 2005 ...

Страница 43: ... 43 Manual P N 22189203 01 17 2005 ...

Страница 44: ...22173538 44 Manual P N 22189203 01 17 2005 ...

Страница 45: ...UNLOADER ASSEMBLY 45 Manual P N 22189203 01 17 2005 ...

Страница 46: ...Separator Tank 46 Manual P N 22189203 01 17 2005 ...

Страница 47: ... 47 Manual P N 22189203 01 17 2005 ...

Страница 48: ... 48 Manual P N 22189203 01 17 2005 ...

Страница 49: ...AIR OIL HYDRAULIC PIPING 49 Manual P N 22189203 01 17 2005 ...

Страница 50: ...AIR OIL HYDRAULIC PIPING 50 Manual P N 22189203 01 17 2005 ...

Страница 52: ... 52 Manual P N 22189203 01 17 2005 Wiring Diagram ...