SECTION 5 – OPERATING INSTRUCTIONS

SET - UP

Place the unit in an open, well-ventilated area. Position as

level as possible. The design of these units permits a 15-

degree sidewise limit on out-of-level operation.

When the unit is to be operated out of level it is im-

portant:

(1) To have the compressor oil level gauge show no more

than mid-scale.

(2) Do not overfill the compressor lubricating oil system.

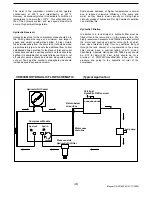

BEFORE STARTING

Do not connect the air discharge on this unit into a

common header with any other unit of any description, or

any other source of compressed air, without first making

sure a check valve is used between the header and the

unit. If this unit is connected in parallel with another unit of

higher discharge pressure and capacity, a safety hazard

could occur in a back-flow condition.

Safety valve setting is 220 psig (1517 kPa). Assure

external air system is safe under all operating conditions

to prevent serious hazard to operations personnel.

Unrestricted airflow from a hose will result in a whip-

ping motion of the hose, which can cause serious

injury or death. A safety device must be attached to

the hose at the source of supply to reduce pressure in

case of hose failure or other sudden pressure release.

Reference: OSHA regulation 29 CFR Section 1926.302

(b).

• Open manual blowdown valve to ensure pressure is

relieved in receiver separator system. Close valve in order

to build up full air pressure and ensure proper oil

circulation.

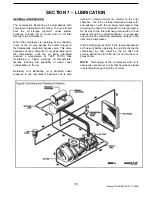

• Check the compressor lubricating oil level. The proper oil

level is mid-way to low on the green zone of level gage.

Add oil if the level falls to the red zone. Do NOT overfill.

This machine

produces

loud noise. Extended ex-posure to loud noise can

cause hearing loss. Wear hearing protection.

Be sure no one is IN or ON the compressor unit.

Always operate this equipment with all enclosure panels

installed to avoid recirculation of hot air. This will maximize

the life of the compressor.

Do NOT operate machine with guards removed.

Do not operate machine with safety shutdown switches

by-passed.

(

24

)

Manual P/N 22189203 (01/17/2005)

Содержание HP60CMH

Страница 6: ... 6 Manual P N 22189203 01 17 2005 ...

Страница 7: ... 7 Manual P N 22189203 01 17 2005 ...

Страница 8: ... 8 Manual P N 22189203 01 17 2005 ...

Страница 9: ... 9 Manual P N 22189203 01 17 2005 9 Manual P N 22189203 01 17 2005 ...

Страница 10: ... 10 Manual P N 22189203 01 17 2005 10 Manual P N 22189203 01 17 2005 ...

Страница 41: ... 41 Manual P N 22189203 01 17 2005 ...

Страница 42: ...22147409 90CFM Cooler Assembly 22489389 60CFM Cooler Assembly 42 Manual P N 22189203 01 17 2005 ...

Страница 43: ... 43 Manual P N 22189203 01 17 2005 ...

Страница 44: ...22173538 44 Manual P N 22189203 01 17 2005 ...

Страница 45: ...UNLOADER ASSEMBLY 45 Manual P N 22189203 01 17 2005 ...

Страница 46: ...Separator Tank 46 Manual P N 22189203 01 17 2005 ...

Страница 47: ... 47 Manual P N 22189203 01 17 2005 ...

Страница 48: ... 48 Manual P N 22189203 01 17 2005 ...

Страница 49: ...AIR OIL HYDRAULIC PIPING 49 Manual P N 22189203 01 17 2005 ...

Страница 50: ...AIR OIL HYDRAULIC PIPING 50 Manual P N 22189203 01 17 2005 ...

Страница 52: ... 52 Manual P N 22189203 01 17 2005 Wiring Diagram ...