31

9.

If equipped with drum band brake, attach band brake

assembly (104) as described in the ‘Drum Band Brake

Assembly’ section.

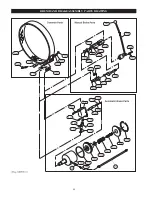

Drum Band Brake Assembly (optional feature)

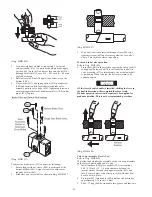

Refer to Dwg. MHP0631.

Automatic Drum Band Brake:

For ease of assembly install bracket (106) and cylinder (121)

assemblies to motor end upright (68) prior to assembling upright

to drum.

1.

Assemble the brake cylinder (121) as follows:

a.

Install ‘O’ ring (122) on piston (123).

b.

Heavily coat the piston and cylinder rod with

“LubriPlate” MO-LITH No. 2 or equivalent lubricant.

Install ‘O’ rings (109) and (110) on cylinder rod (108).

Place cylinder rod (108) into piston (123) and secure

in place using retainer ring (111).

c.

Install piston assembly in brake cylinder (121).

d.

Install washer (128) and springs (124) and (127).

DANGER

• Springs (124) and (127) exert a considerable force on cover

(125) when assembled . Extreme care must be taken when

assembling and installing cover (125) and retainer ring (126).

e.

Using a press, slowly compress cover (125) and

springs until the retainer ring groove is accessible.

Install retainer ring (126). To ensure that retainer ring

is properly installed, tap the end of the retainer ring

with a punch until the entire retainer ring rotates in

brake cylinder groove. Slowly release press and ensure

retainer ring securely holds cover in place.

2.

If not accomplished during ‘Winch Assembly’ steps, install

bracket (106) to inside of motor end upright (68) and

secure in place using capscrews (107) and (112). Torque

capscrews to 85 ft lbs (115 Nm).

3.

Assemble roller (116) in plunger (114) and secure using

dowel pin (115). Heavily coat the plunger assembly with

“LubriPlate” MO-LITH No. 2 or equivalent lubricant.

Install spring (113) and plunger assembly in brake bracket

(106). Align groove in plunger towards hole in motor end

(68) upright.

4.

Align cylinder rod roller surface to groove in plunger. Turn

cylinder (121) clockwise until snug. Adjust cylinder (121)

such that the air hose connection port is horizontal and

towards the motor.

Conduct the following when the winch is assembled, but

prior to mounting to the foundation. The motor end of the

winch should be raised enough to allow access to the brake

components located on the inside surface of the inboard

(motor end) upright (68).

5.

Place spacer (105) between upper brake band flange and

bracket. Attach band assembly (104) to bracket (106) using

three capscrews (101), spacers (102) and spacer tubes

(103). Torque capscrews to 55 ft lbs (75 Nm).

6.

Install pivot bar (119) and capscrew (120) through lower

flange of brake band assembly (104). At lowest point of

threads, place a bead of Loctite® 680 and install jam nut

(117) fully. Jam nut threads must become coated with

sealant. Install second jam nut (117) to approximately the

middle of the thread length. Thread capscrew (120) into

bottom of plunger (114) a minimum of five thread lengths.

Lock in place, against plunger, using jam nut (117). Adjust

brake as described in the ‘Drum Band Brake Adjustment’

section.

Manual Drum Band Brake:

1.

Coat the bearings with “LubriPlate” MO-LITH No. 2 or

equivalent lubricant and install bearings (138) and (140) in

brake bracket (106). Install ‘O’ rings (137) and (141) in

brake bracket (106).

2.

Install eccentric shaft (135) in brake bracket (106).

3.

Install cam plate (131) on end of shaft (135). Install washer

(133), bearing sleeve (134) and retainer ring (132).

4.

Install assembly onto motor end upright (68) and secure in

place with capscrews (107) and (112).

5.

Attach brake band assembly (104) using capscrew (120).

Thread capscrew into cam plate only as necessary to hold

components together.

6.

Attach other end of band brake assembly (104) to brake

bracket (106) using capscrews (101), spacers (102), (103)

and (105). Torque capscrews at 52 to 57 ft lbs (70 to 78

Nm).

7.

Install brake handle (142) on shaft (135).

8.

Install assembly onto winch drum. Align brake bands on

drum brake surface. Install brake handle (142). Adjust

brake as described in the following ‘Adjusting Drum

Brake’ section.

Adjusting Drum Brake

1.

Pull back on handle to engage drum brake. Brake should

lock (eccentric going over center).

2.

With brake locked, the winch should support 125% of rated

load.

3.

To increase brake band load holding capacity tighten

capscrew (120).

4.

Once brake is adjusted to hold 125% of rated load, lock

adjustment by tightening capscrew (130). This causes

locking pellet (129) to press on capscrew (120) threads,

preventing movement but not damaging threads.

5.

Push forward on handle to release brake. Remove handle

(142) from eccentric shaft (135) and position it on shaft

such that the lower half is in a vertical position.

6.

Secure handle to shaft using capscrew (130) and washers

(143).

NOTICE

• When properly adjusted the brake should require

approximately 35 lbs (16 kg) of force to engage and ‘LOCK’

(eccentric going over center).

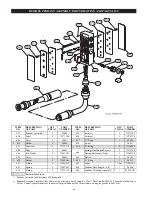

Disc Brake Assembly

Refer to Dwg. MHP1230.

1.

Install bearing (21) into support plate (19) and secure with

retainer ring (22).

2.

In this order, place spacer (11), sprag clutch (16), outer race

(12) and spacer (11) on inner race (10). Test sprag clutch

operation. Refer to Dwg. MHP1197.

NOTICE

• Correct sprag clutch installation prevents clockwise

rotation (brake engages) and allows counterclockwise

rotation when viewed from the cover (2) end of the brake

assembly.

WARNING

• Incorrect assembly of the sprag clutch will adversely affect

winch operation. In haul-in operation, sprag clutch will be

engaged resulting in restricted winch operation. In neutral

and payout positions, the sprag clutch can rotate resulting in

brake not holding load. Ensure the sprag clutch is correctly

installed.

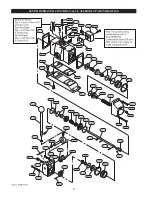

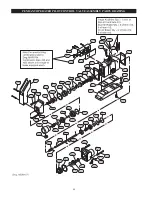

Содержание force5 FA5A-LAK1

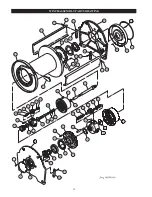

Страница 34: ...34 WINCH ASSEMBLY PARTS DRAWING ...

Страница 36: ...36 MOTOR ASSEMBLY PARTS DRAWING ...

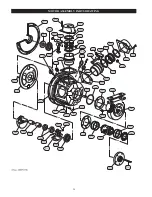

Страница 38: ...38 DISC BRAKE ASSEMBLY PARTS DRAWING ...

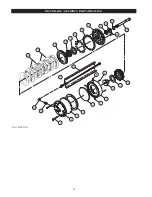

Страница 40: ...40 DRUM BAND BRAKE ASSEMBLY PARTS DRAWING ...

Страница 42: ...42 LEVER OPERATED CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Страница 44: ...44 PENDANT OPERATED PILOT CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Страница 48: ...48 SHUTTLE VALVE ASSEMBLY PARTS DRAWING ...

Страница 50: ...50 EMERGENCY STOP AND OVERLOAD ASSEMBLY PARTS DRAWING ...

Страница 52: ...52 OPEN FRAME FACE WINCH ASSEMBLY PARTS DRAWING ...

Страница 57: ...57 WINCH LABEL TAG LOCATION AND PART NUMBER REFERENCE DRAWING ...