51

1.

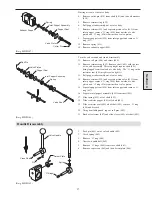

Place planet gear (39) on the cardboard square and insert pin

tool.

2.

Insert 5 to 7 needle bearings (41) into gear around pin tool,

ensure first few needle bearings do not tip over.

3.

Insert spacer (59) followed by all 24 needle bearings.

(Dwg. MHP1164)

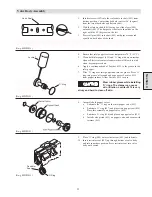

4.

Place a thrush washer (either 34,40 or 42) on top of this

followed by another cardboard square.

5.

Pinching both cardboard squares, flip assembly over. Finish

inserting the remaining needle bearings.

6.

Place another thrust washer on top of assembly. Carefully slide

assembly right into the output carrier (37).

(Dwg. MHP1161)

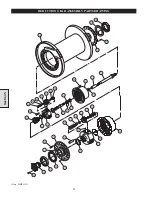

7.

Align the bores and push out the pin tool using the output

planet pin (35). Measure the side clearance and adjust the

thrust washers (34, 40, or 42) to provide 0.005 - 0.032 inches

(0.13 - 0.81 mm). Spin gears, gears should rotate freely.

(Dwg. MHP1169)

8.

Measure the distance that roll pin (38) must be tapped into

carrier so that the roll pin is half in the carrier and half in the

pin, and mark the punch.

(Dwg. MHP1165)

9.

Tap roll pin (38) into output carrier (37) to the mark on the

punch.

(Dwg. MHP1166)

Section 5

Punch

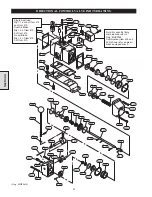

Содержание FA5A

Страница 10: ...10 DISC BRAKE PARTS DRAWING Dwg MHP0667 Dwg MHP0630 One Way Clutch Detail Section 1...

Страница 19: ...19 Section 2 SERVICE NOTES...

Страница 54: ...54 REDUCTION GEAR ASSEMBLY PARTS DRAWING Dwg MHP1221 Section 5...

Страница 57: ...57 SERVICE NOTES...

Страница 58: ...58 SERVICE NOTES...

Страница 59: ...59 SERVICE NOTES...