41

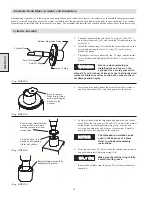

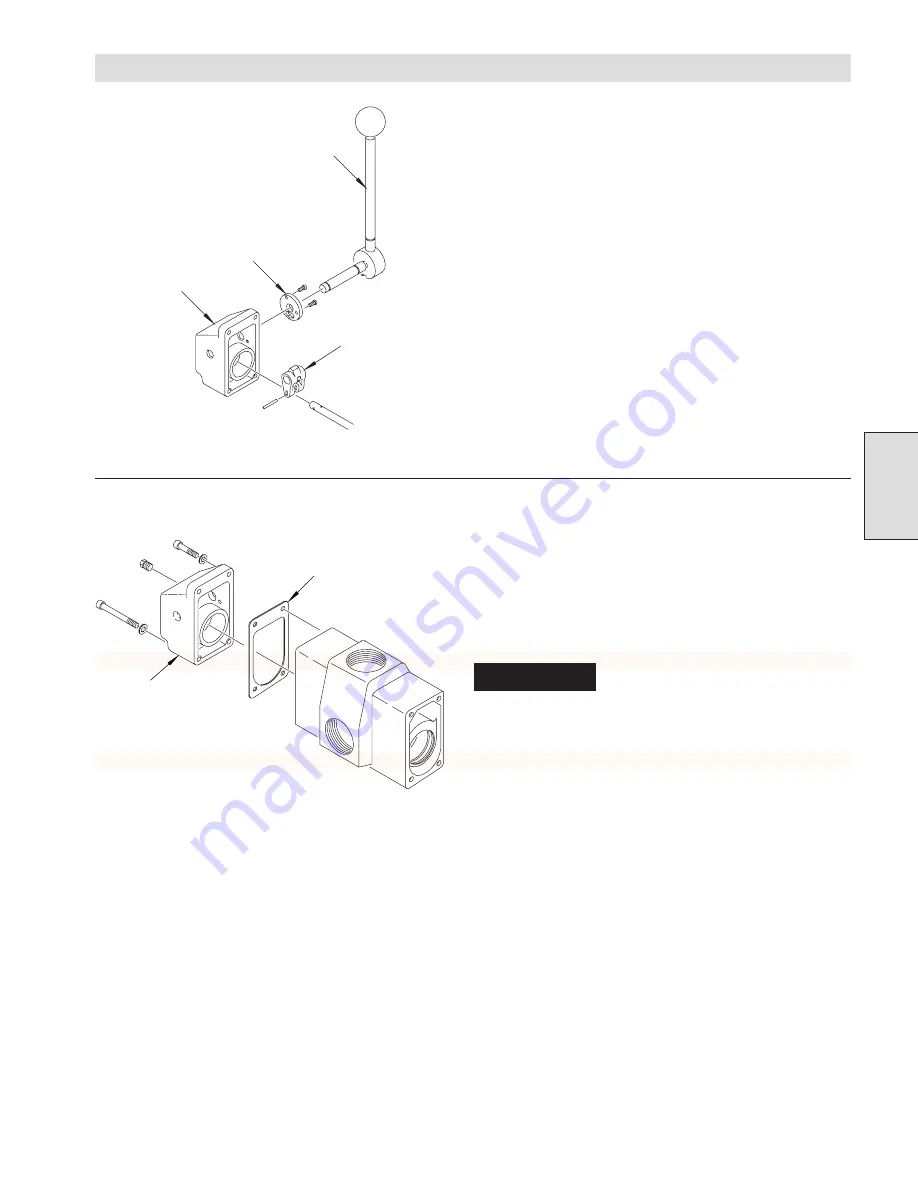

Control Handle End Cap Assembly

1.

Place the split portion of valve clevis (446) over shaft (401),

with large portion on top of shaft and rounded portion of valve

clevis facing valve body. Apply Loctite

®

609 on roll pin (409).

Tap roll pin (409) through valve clevis and shaft until centered

in clevis.

2.

Apply Loctite

®

680 on threads of capscrews (465) and insert

into detent plate (464). Insert cross shaft (461) without ‘O’

rings into end cap (450). Place detent plate on cross shaft and

align with mounting holes in end cap (450). Insert capscrews

(465) and tighten to 42 to 45 in. lbs. (15.5 to 16.7 Nm). Ensure

that cross shaft rotates freely and then remove.

(Dwg. MHP1156)

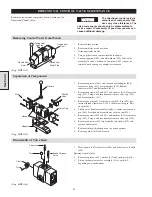

3.

Place valve body (410) on its side with the clevis end over the

edge of the workbench.

4.

Place gasket (411) on valve cap (450) and slide assembly over

clevis. Lubricate threads and loosely install capscrews (437)

and (439) and washers (433).

5.

From the bottom hole in valve cap use a punch, or similar tool,

to align the cross shaft holes in valve cap with the hole in the

clevis. Use tool to maintain position and tighten capscrews to

54 to 60 inch lbs (20 to 22 Nm).

NOTICE

The slotted pin grooves in the

clevis (where clevis and shaft

(401) are joined) make alignment

of the cross shaft and clevis difficult. To prevent binding

of cross shaft during installation, ensure the cross shaft

holes (located in valve cap) and the clevis hhole are

aligned before installing cross shaft.

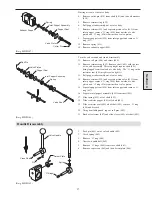

6.

Lubricate ‘O’ rings (448) and locate in grooves on cross shaft

(461). Insert cross shaft through detent plate side of valve cap

assembly. To complete, raise handle assembly up and insert

pin (463) into detent plate while pushing on cross shaft.

7.

Align the hole in the cross shaft with the hole in the end of the

clevis. Apply a bead of Loctite

®

242 to pin (445). Using a

8-32 x 2 inch screw attached to the threaded end of pin, install

pin by tapping into position. Ensure pin is inserted fully into

clevis.

8.

Operate the lever in both directions. There should be no

indication of sticking or binding. When released, the lever

must return to the neutral position and lock in place (handle

must be lifted before shifting in either direction).

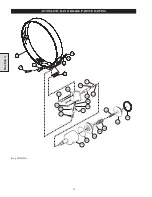

(Dwg. MHP1157)

9.

Place pipe thread sealant on the threads of plug (447), insert it

into end cap (450) and tighten.

Section 4

Clevis

Detent Plate

End Cap

Valve Handle

Gasket

End Cap

Содержание FA5A

Страница 10: ...10 DISC BRAKE PARTS DRAWING Dwg MHP0667 Dwg MHP0630 One Way Clutch Detail Section 1...

Страница 19: ...19 Section 2 SERVICE NOTES...

Страница 54: ...54 REDUCTION GEAR ASSEMBLY PARTS DRAWING Dwg MHP1221 Section 5...

Страница 57: ...57 SERVICE NOTES...

Страница 58: ...58 SERVICE NOTES...

Страница 59: ...59 SERVICE NOTES...