23

WARNING

Before troubleshooting the

band brake, remove the wire

rope from the winch drum.

Failure to remove the wire rope before working on the

winch can cause mechanical damage and/or injury.

There are two ways that the band brake can cause problems:

1.

It might not release

2.

It might not hold the load

If one of the above problems is present check the following before

removing any brake components from the winch:

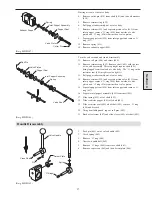

AUTOMATIC BAND BRAKE TROUBLESHOOTING

Check the following before removing any brake components from the winch:

Symptom

Cause

Remedy

The brake does not

release.

The air line is not connected to the brake.

Make sure the air line is connected to the brake.

The air line is blocked, pinched, or torn.

Make sure that the air line is not blocked, torn or

pinched. Replace the air line if necessary.

The brake is not adjusted properly.

Adjust the brake.

The band brake does not

hold the load.

The brake band (104) has worn past safe

limits.

Adjust the brake band (refer to proper section). Replace

the band if it measures less than 1.5 mm (1/16 inch)

thick anywhere on the band lining, or if it can no longer

be adjusted.

The adjustment bolt (120) is not locked in

position.

Check the adjustment bolt lock nuts, and tighten them if

needed.

The three anchor capscrews (101) are loose.

Inspect the anchor capscrews. If necessary, torque them

to 45-50 Nm (33-36 ft lbs.)

The three tubular spacers (103) have collapsed

or are worn.

Inspect the tubular spacers. They should measure

between 28.3 and 28.8 mm (1.115 and 1.135 inches).

If they have collapsed or are worn, replace them.

The brake activation components in the winch

control valve are out of adjustment, or the

control handle is not returning to neutral.

Refer to the manual for instructions on troubleshooting

and adjusting the brake actuation components in the

winch control valve.

The orifice and dump valve assembly are not

relieving air pressure from the brake.

To check, operate the winch control valve handle or

pendant control, while feeling and listening for air

escaping from the dump valve. If no air is, detected,

replace the orifice and dump valve assembly.

Section 3

If the air pressure is adequate and the brake is properly adjusted, remove the pneumatic release assembly from the winch and continue

troubleshooting.

Symptom

Cause

Remedy

The band brake does not

release.

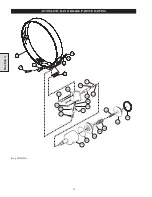

Air is leaking past the piston (123) inside the

cylinder (121).

Replace the ‘O’ rings (109, 110, and 122) that prevent air

from leaking inside the cylinder.

The retainer ring (111) that fastens the cylinder

rod (108) to the piston (123) has failed.

Replace the retainer ring.

The cylinder rod (108) is sticking inside the

cylinder (121).

Make sure the cylinder rod slides smoothly inside the

cylinder.

The plunger (114) is sticking inside the brake

bracket (106).

Make sure the plunger slides smoothly inside the brake

bracket.

The spring (113) has collapsed or is bent.

Replace the spring.

The band brake does not

hold the load.

The springs in the pneumatic release assembly

have collapsed.

Check the spring length. The springs (124) and (127)

should measure 203 mm (8.0 inches). If either spring

measures less than this dimension, replace.

The cylinder rod (108) is sticking in the

cylinder (121).

Make sure the cylinder rod is lubricated properly and

slides smoothly inside the cylinder.

The plunger (114) is sticking inside the brake

bracket (106).

Make sure that the plunger is lubricated properly and

slides smoothly inside the brake bracket.

The roller (116) or dowel pin (115) is worn or

broken.

Inspect the roller and dowel pin for wear. Replace if

necessary.

Содержание FA5A

Страница 10: ...10 DISC BRAKE PARTS DRAWING Dwg MHP0667 Dwg MHP0630 One Way Clutch Detail Section 1...

Страница 19: ...19 Section 2 SERVICE NOTES...

Страница 54: ...54 REDUCTION GEAR ASSEMBLY PARTS DRAWING Dwg MHP1221 Section 5...

Страница 57: ...57 SERVICE NOTES...

Страница 58: ...58 SERVICE NOTES...

Страница 59: ...59 SERVICE NOTES...