114 |

www.HandiQuilter.com

9.

Adjust the sensor if necessary (if the LED is constantly on and will not turn off, the sensor is too close

to the tension discs. If it will not trigger on when the thread is pulled, the sensor should be adjusted

closer to the check spring).

10.

Reinstall the front panels. (See

To install the front plastic panels

in section 23,

Front Plastic Panels

.)

To remove the thread break sensor

1.

Remove the front plastic panels. (See

To remove the front plastic panels

in section 23,

Front Plastic

Panels

.)

2.

Loosen the thread break sensor set screw using a 2mm hex tool.

3.

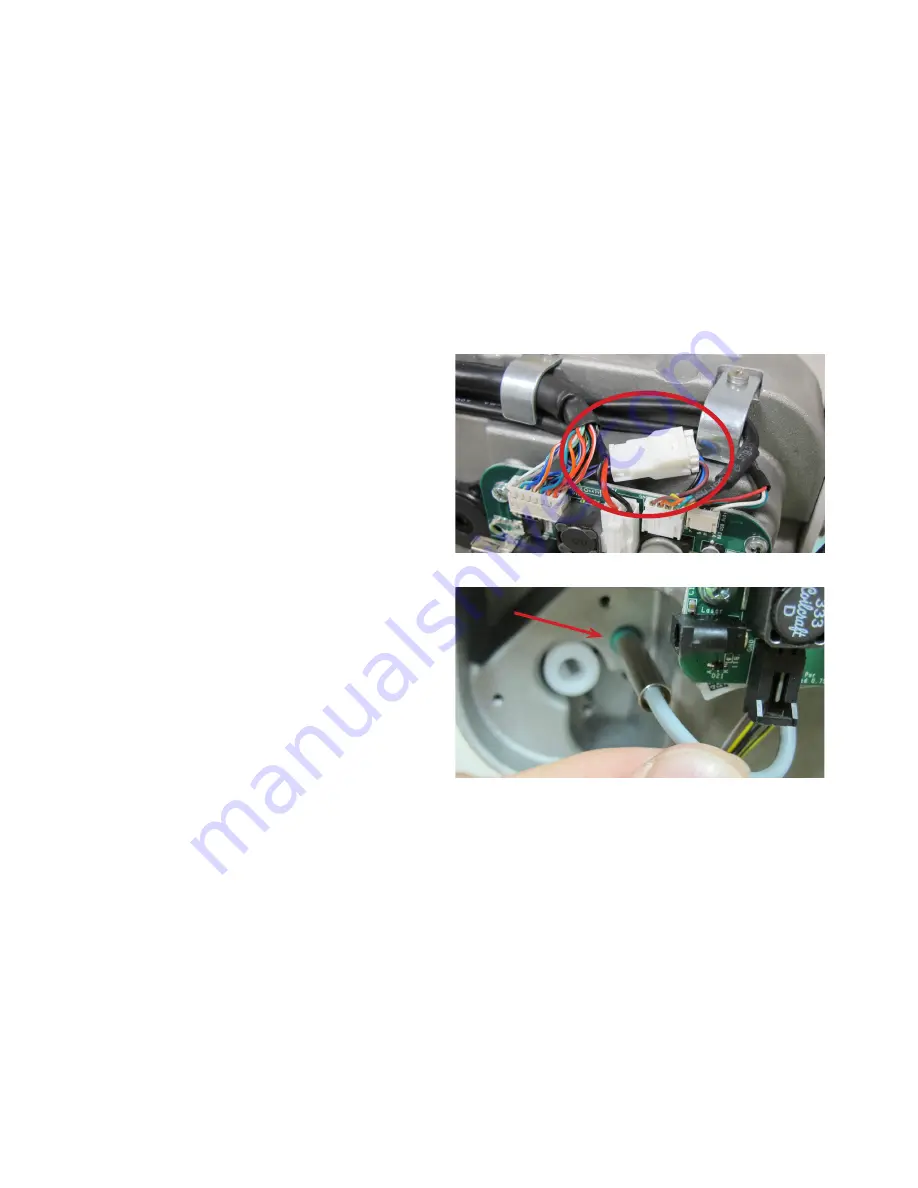

Disconnect the sensor cable at the top of the

head frame, just above the front distribution

board. The cable has a white 4-pin connector

with three wires attached.

4. Pull the sensor out from the left-hand side of

the head frame by gently pulling on the sensor

cable. If necessary, use a small blunt tool (such

as a 2mm or 2.5mm hex tool) to gently push the

green end of the sensor on the right side of the

head frame while pulling on the gray cable on

the left side of the head frame and remove the

sensor from the head frame.

5.

Because the sensor cable is routed behind the front distribution board, it is necessary to remove the

four screws from the front distribution board with a #1 Phillips screwdriver to completely remove the

sensor.

To install the thread break sensor

1.

Plug the sensor cable into the 4-pin connector at the top of the head frame.

2.

Route the sensor cable behind the front distribution board, being careful not to pinch any wires

between the board and screw standoffs.

3.

Reattach the front distribution board with a #1 Phillips screwdriver and the four Phillips screws.