17

industrialaircontractor.com

Please contact 1-888-895-4549 for further assistance.

Maintenance

GENERAL MAINTENANCE

□

Condensate forms in the tank when

there is humidity in the air. Depending

on the environmental conditions, drain

the condensate daily and/or every hour.

For instructions, see

Draining the tank

on page 16.

□

The safety valve automatically releases air

when the receiver pressure exceeds the preset

maximum.

□

Inspect the tank annually for rust, pin holes,

or other imperfections that could cause it to

become unsafe.

□

Avoid using solvents when cleaning plastic

parts. Most plastics are susceptible to damage

from various types of commercial solvents and

may be damaged by their use.

□

Use clean cloths to remove dirt, dust, oil,

grease, etc.

LUBRICATION

This compressor requires oil to be in the crank case

in order to lubricate the pump for operation (see

REFILLING THE COMPRESSOR PUMP WITH OIL

on page

11). It is also necessary to change this oil after the

first 10 hours of use and every 100 hours after that.

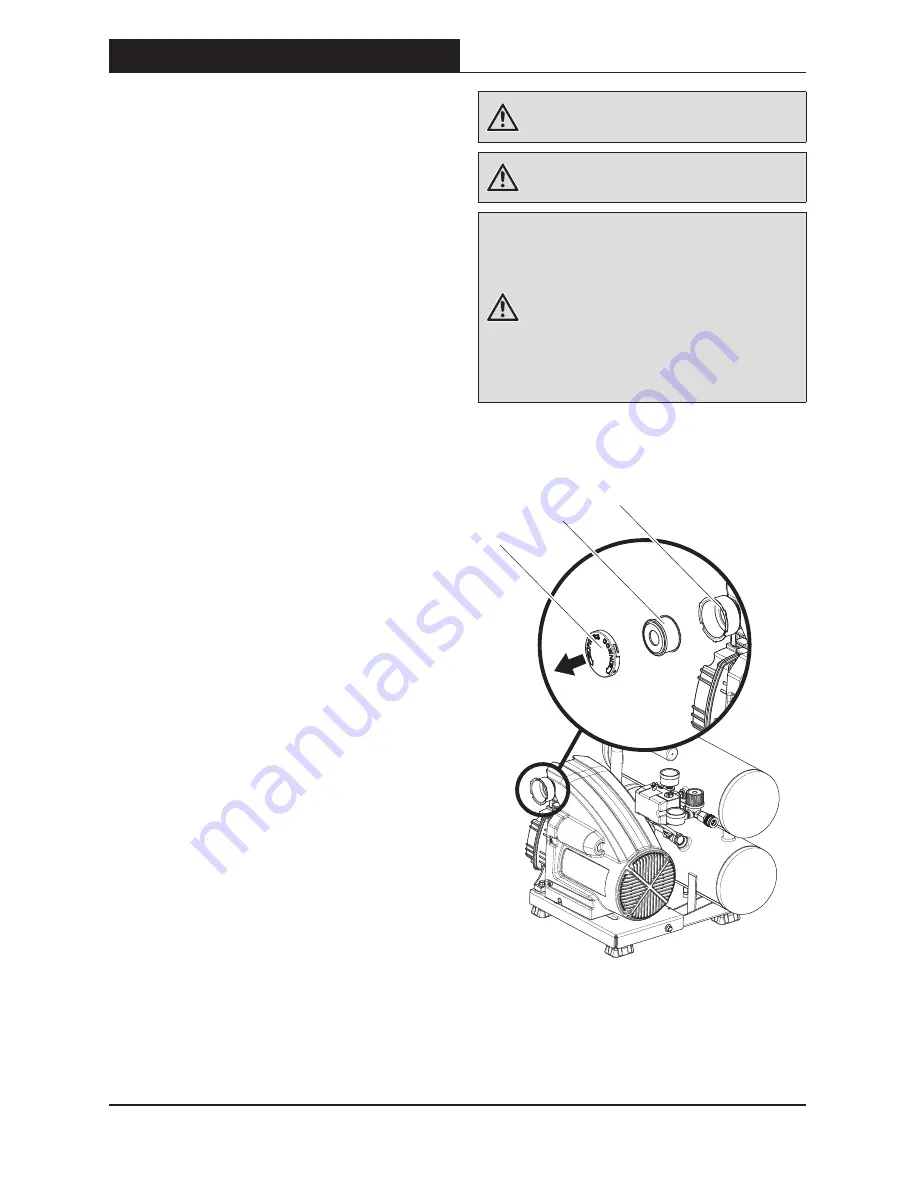

CLEANING THE AIR FILTER

From time to time, the air filter needs to be removed

and cleaned.

□

Turn the air compressor OFF ( O ).

□

Unplug the air compressor.

□

Unsnap the air filter cover (1) to remove.

□

Remove the air filter (2) from the air filter

housing (3).

□

Blow compressed air through the air filter for

10-15 seconds using an approved OSHA nozzle.

2

1

3

WARNING:

When servicing, use only identical Industrial

Air Contractor replacement parts. Use of any other parts

may create a hazard or cause product damage.

WARNING:

Always release all pressure, disconnect from

the power supply, and allow the unit to cool to the touch

before cleaning or making repairs on the air compressor.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc., come

in contact with plastic parts. Chemicals can damage,

weaken or destroy plastic which may result in serious

personal injury. Electric tools used on fiberglass material,

wallboard, spackling compounds, or plaster are subject to

accelerated wear and possible premature failure because

the fiberglass chips and grindings are highly abrasive to

bearings, brushes, commutators, etc. Consequently, we

do not recommended using this tool for extended work on

these types of materials. However, if you do work with any

of these materials, it is extremely important to clean the

tool using compressed air.