31

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

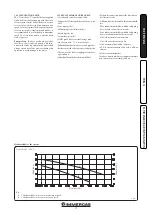

Programming menu

Menu item

Description

Adjustment range

Default value

Customised

Value

P01 Set Risc (CH Set)

This defines the boiler's flow temperature during heating

20 ÷ P02 °C

85

P02 Set risc Max (Max

CH Set)

This defines the maximum settable flow temperature during heating

20 ÷ 95 °C

85

P03

Isteresi

riscaldamento

(Heating Hysteresis)

This defines the power-off hysteresis during the heating phase

2 ÷ 10 °C

5

P04

Anti cicli

riscaldamento (Anti-

cycle CH)

This is used to set a waiting time to avoid the boiler from switching on

multiple times and frequently during CH mode

0 ÷ 15 minutes

3 minutes

P05 Tempo min risc (CH

min time)

This is the amount of time that the boiler needs to stabilise, when the burner

runs at minimum power for the set amount of time

3 ÷ 10 minutes

3 minutes

P06

Rampa

riscaldamento (CH

ramp)

The amount of time that the boiler takes to reach the required temperature,

number of degrees per minute (0 means no ramp)

0 ÷ 60 °C/minute

4 °C/minute

P07

Post circolazione

riscaldamento (CH

post-circulation)

The amount of CH post circulation once the CH phase is fnished

1 ÷ 30 minutes

3 minutes

P08

Pot risc max

disponibile (Available

max heat out)

This defines the maximum power percentage to be used during the set CH

phase

P09 ÷ 100%

100%

P09

Pot risc min

disponibile (Available

max heat out)

This defines the minimum power percentage to be used during the set CH

phase

0 ÷ P08%

0%

P10 Minimum system

flow rate

This defines the minimum system flow rate required to power-on the boiler

Attention:

do not change this parameter

5

÷

47 l/minutes

14 l/minutes

P11

Anti umidità elettrodi

(Electrodes anti-

humidity)

This defines fan speed and operating mode, to avoid humidity inside

the condensing module, which could otherwise cause the electrodes to

malfunction (0 = disabled function, recommended value = 40) (RPM speed is

calculated by multiplying the value displayed by 50)

P26

÷

120

0

P12 Boiler’s modulation

ratio

It defines the boiler’s modulation ratio

(Do not modify)

0

÷

100%

10%

P13 Boiler power

Used to calculate the boiler power in the event of simple cascade.

0

÷

255 kW

35 kW = 35

55 kW = 50

P14 External probe curve

This is used to select the external probe operating curve (optional) (0 =

disabled probe)

0

÷

10

0

P15 External probe offset

This defines the CH offset in relation to the selected external probe curve

20

÷

70 °C

30 °C

P16 Set San (DHW set)

This defines the DHW temperature

20 ÷ 65 °C

65 °C

P17 P17 External D.H.W /

3-waypump

- With single boiler and common flow probe, it lets you choose between an

external D.H.W pump and a 3-way one.

- With a simple cascade, it manages a D.H.W. pump (downstream an

hydraulic separator).

0 = 3 Ways

1 = D.H.W. pump

P18 Isteresi sanitario

(DHW hysteresis)

This defines the DHW power-on hysteresis during CH

2 ÷ 10 °C

5 °C

P19

Post circolazione

sanitario (DHW post-

circulation)

This is the post circulation time during DHW once DHW production is

finished

0

÷

180 seconds

60 seconds

P20

Pot san max

disponibile (Available

max DHW pow)

This defines the maximum power percentage to be used during the set DHW

phase

P21

÷

100 %

50 %

P21

Pot san min

disponibile (Available

max DHW pow)

This defines the minimum power percentage to be used during the set DHW

phase

0

÷

P20 %

0 %

P22

DHW flow

temperature with

thermostat

In combination with a storage tank and a separate thermostat, this defines the

flow temperature during DHW operation

35

÷

90 °C

80 °C

P23 Modulazione sanitario

(DHW modulation)

Summed with the “Set San” (P16) parameter, this defines the flow

temperature set that the boiler has to modulate the power on during DHW

5

÷

30 °C

15 °C

P24

Incremento off

sanitario (DHW off

increment)

This defines the time that the boiler allows the burner to switch off during

DHW, by an increment of 5 °C on top of the flow temperature

0

÷

255 seconds

60 seconds

P25

Velocità Max

ventilatore (Min fan

Speed)

This defines the max fan speed and therefore the maximum relative boiler

operating power (RPM speed is calculated by multiplying the value displayed

by 50)

P26

÷

255 RPM x 50

35 kW Met. 101

35 kW LPG 98

55 kW Met. 131

55 kW LPG 129

Содержание VICTRIX PRO 35 1 I

Страница 1: ...VICTRIX PRO 35 55 1 I IE Instruction and warning book 1 038715ENG...

Страница 2: ......

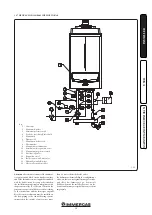

Страница 37: ...37 3 10 1 6 8 9 9 12 12 10 11 13 13 13 13 A A Rif A 7 7 INSTALLER USER MAINTENANCE TECHNICIAN Ref A...

Страница 42: ......

Страница 43: ......