10

(A)

(B)

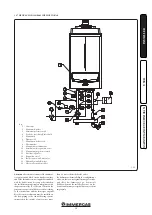

1-9

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

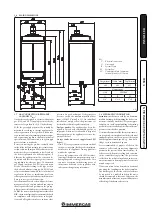

1.12 IMMERGAS FLUE SYSTEMS.

Immergas can supply various solutions for flue-

ing and air supply.

Attention: the boiler must be installed ex-

clusively with an original Immergas “Green

Range” air intake device and fumes extraction

system, as required by the standard in force.

The plastic pipes cannot be installed outdoors,

for lengths longer than 40 cm, without suitable

protection from UV rays and other atmos-

pheric agents.

This system can be identified by an identifi-

cation mark and special distinctive marking

bearing the note: “only for condensing boilers”.

•

Configuration type B, open chamber and fan

assisted.

The boiler leaves the factory with type

“B

23

” configuration.

Air intake takes place directly from the envi-

ronment in which the boiler is installed via

relevant slots made in the back of the boiler

and flue exhaust in the individual flue or to the

outside. Boiler with this type of configuration

are classified as type B

23

(in accordance with

standard EN 297 and relative standards in

force).

With this configuration:

- air intake takes place directly from the room

in which the appliance is installed;

- the flue exhaust must be connected to its own

individual flue or channelled directly into the

external atmosphere.

- Type B open chamber boilers must not be

installed in places where commercial, artisan

or industrial activities take place, which use

products that may develop volatile vapours

or substances (e.g. acid vapours, glues, paints,

solvents, combustibles, etc.), as well as dusts

(e.g. dust deriving from the working of wood,

coal fines, cement, etc.), which may be harm-

ful for the components of the appliance and

jeopardise operation.

•

Type C configuration, sealed chamber and

fan assisted.

The boiler leaves the factory with

"B

23

" configuration, to change the configuration

of the boiler to type "C" (sealed chamber and

fan assisted), disassemble the 80 Ø adapter, the

bracket and the gasket present on the boiler

cover and install the designated flue.

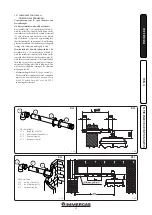

• Coupling extension pipes and concentric

elbows. To install push-fitting extensions with

other elements of the flue, proceed as follows:

Install the concentric pipe or elbow with the

male side (smooth) on the female section

(with lip seal) to the end stop on the previously

installed element in order to ensure sealing

efficiency of the coupling.

Attention:

if the exhaust terminal and/or

concentric extension pipe needs shortening,

consider that the internal duct must always

protrude by 5 mm with respect to the external

duct.

•

N.B.:

for safety purposes, do not obstruct the

boiler intake-exhaust terminal, even temporar-

ily.

•

N.B.:

when installing horizontal pipes, a min-

imum inclination of 3% must be maintained

and a section clamp with pin must be installed

every 3 metres.

•

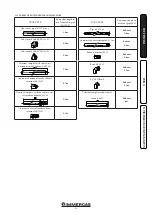

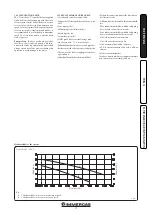

Maximum extension.

Each individual compo-

nent has a resistance corresponding to a certain

length in metres of pipe with the same diameter

(par. 1.13). With installations that involve using

various types of parts, deduct the length of

the added part from the maximum admissible

length of the kit.

Example: if you need to add a 90° bend to

a concentric system 125 Ø you will need to

deduct 1.9 m from the maximum admissible

length.

•

Positioning of the gaskets (black) for “green

range” flue extraction systems.

Position the

gasket correctly (for bends and extensions)

(Fig. 1-9):

- gasket (A) with notches, to use for bends;

- gasket (B) without notches, to use for exten-

sions;

N.B.:

if component lubrication (already carried

out by the manufacturer) is not sufficient, re-

move the residual lubricant using a dry cloth,

then to ease fitting coat the parts with talc,

supplied in the kit.

Содержание VICTRIX PRO 35 1 I

Страница 1: ...VICTRIX PRO 35 55 1 I IE Instruction and warning book 1 038715ENG...

Страница 2: ......

Страница 37: ...37 3 10 1 6 8 9 9 12 12 10 11 13 13 13 13 A A Rif A 7 7 INSTALLER USER MAINTENANCE TECHNICIAN Ref A...

Страница 42: ......

Страница 43: ......