74

INS

TALLER

U

SER

M

AINTEN

AN

CE

TECHNI

CI

AN

TECHNI

CAL

D

AT

A

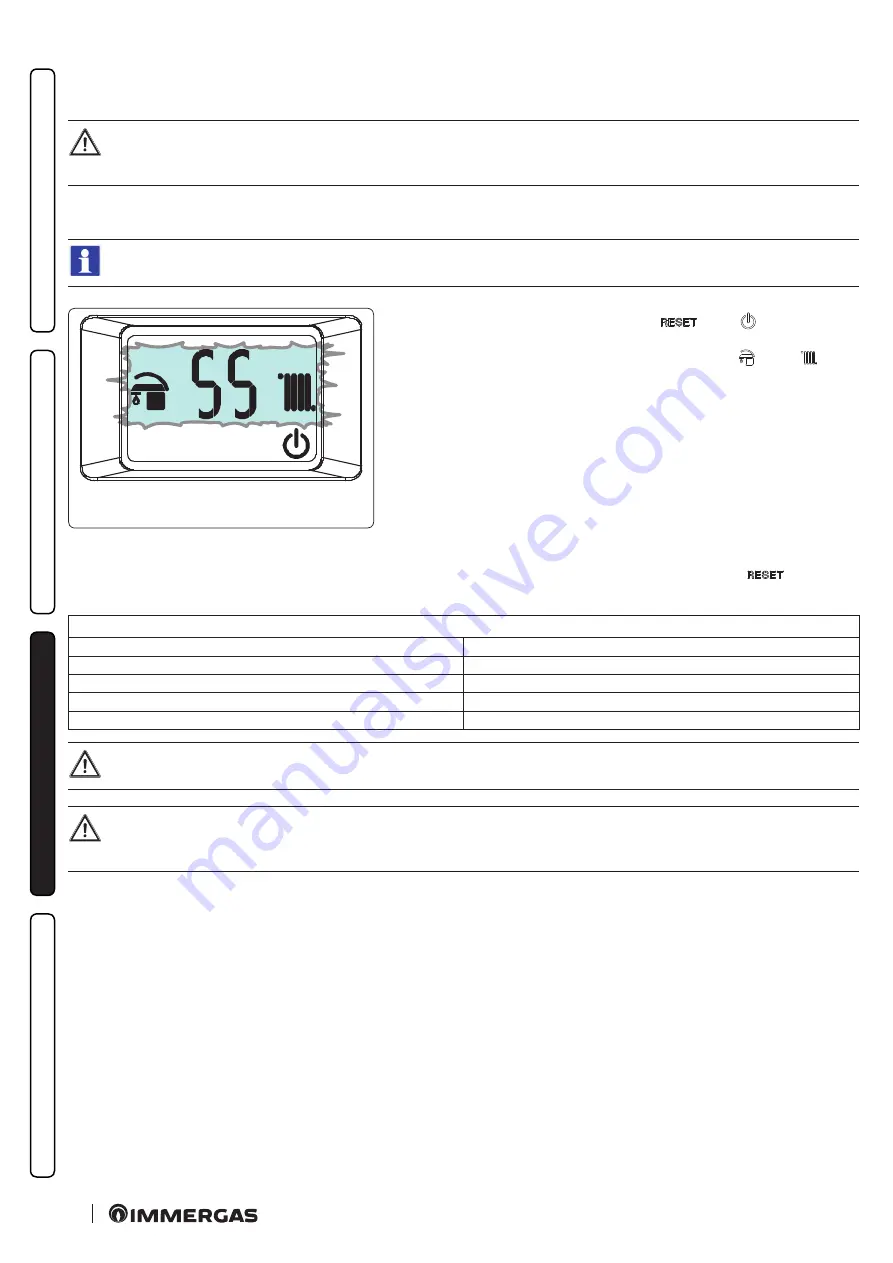

3.12 FLUE TEST

To define the value to set in the ”flue length” “F0” parameter, detect the parameters during the “flue test”.

Before performing the test, ensure that the condensate drain trap has been filled correctly and check that there are no obstruc-

tions in the air intake circuit and flue exhaust and that the sealed chamber is perfectly closed and the flue has already been in-

stalled.

Once the test has been carried out properly, note the detected value in the relevant table, in order to have it available for future checks.

To activate this mode, the boiler must be in “Stand-by” mode.

If the boiler is connected to the CAR

V2

the “stand-by” function can only be activated via the remote control panel.

53

To activate the function, press the buttons “

” and “ ” simultaneously

until function activation, which is displayed by indicating the fan operation

speed (in hundreds of revs) and ignition of the flashing “

” and “

” sym-

bols.

The appliance remains in this mode for a maximum period of 15 minutes, keeping the fan speed constant.

This function ends once 15 minutes have elapsed, or by disconnecting supply voltage to the boiler, or by pressing the “

” button.

Check the ΔP between the two pressure test outlets (Fig. 37) and set parameter F0 according to the values shown in the table below:

Victrix Omnia

Parameter F0

Pressure

0

< 90 Pa

1

90 ÷ 120 Pa

2

120 ÷ 150 Pa

Value detected on first check

Examinations are carried out by sealing the holes provided to analyse the flues, making them pneumatically sealed.

Should there be a appliance malfunction, you can carry out a flue test to check that there are no obstructions in the flue system.

Different values to those indicated in the previous tables indicate a flue system malfunction, especially a flue system with exces-

sive load losses or obstructed system.