30

INS

TALLER

U

SER

M

AINTEN

AN

CE

TECHNI

CI

AN

TECHNI

CAL

D

AT

A

1.15 INTERNAL INSTALLATION USING A RECESSED FRAME WITH DIRECT AIR INTAKE

Configuration type B, open chamber and fan assisted

Using a kit separator one can achieve direct air intake (Fig. 16) and flue gas exhaust in a single chimney or directly outside.

In this configuration the boiler is classified as type B

23

.

With this configuration:

- air intake takes place directly from the environment in which the appliance is installed (the recessed frame is ventilated), and only

functions in permanently ventilated rooms;

- the flue gas exhaust must be connected to its own individual chimney and channelled directly into the external atmosphere.

The technical regulations in force must be respected.

16

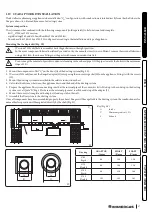

Separator kit installation (Fig. 17).

1. Install the discharge flange on the central hole of the boiler, positioning the relative gasket with the circular projections downwards in

contact with the boiler flange, and tighten using the hex screws with flat tip contained in the kit.

2. Remove the flat flange present in the lateral hole with respect to the central one (according to needs) and replace it with the intake

flange, positioning its gasket already present in the boiler and tighten using the supplied self-threading screws.

3. Fit the bends with male side (smooth) in the female side of the flanges (the intake bend should face the rear side of the boiler).

4. Fit the exhaust pipe with the male side (smooth) to the female side of the bend up to the end stop, making sure that the internal wall

sealing plate has been fitted and connecting the required flue according to personal requirements.

Max. length of exhaust duct.

The flue pipe (both vertical or horizontal) can be extended to a max. length of 36 linear metres.

17