37

INS

TALLER

U

SER

M

AINTEN

AN

CE

TECHNI

CI

AN

TECHNI

CAL

D

AT

A

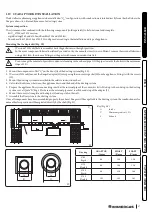

1.19 C9 ADAPTOR KIT INSTALLATION

This kit allows an Immergas appliance to be installed in “C

93

” configuration, with combustion air intake directly from the shaft where the

flue gas exhaust is, obtained by means of a ducting system.

System composition

The system must be combined with the following components (sold separately) to be functional and complete:

- kit C

93

Ø 100 or Ø 125 version;

- rigid ducting Ø 60 and Ø 80 and flexible Ø 50 and Ø 80 kit;

- flue exhaust kit Ø 60/100 or Ø 80/125 configured according to the installation and type of appliance.

Mounting the C

9

adapter kit (Fig. 30)

(Version Ø 125 only) before assembly check the gaskets are in the right position.

In the event component lubrication (already carried out by the manufacturer) is not sufficient, remove the residual lubricant

using a dry cloth, then to ease fitting coat the parts with common or industrial talc.

To encourage the removal of possible condensate forming in the exhaust pipe, tilt the pipes towards the boiler with a minimum

slope of 1.5%.

1. Mount the components of kit "C

9

" on the door (A) of the ducting system (Fig. 30).

2. (Version Ø 125 only) mount the flanged adaptor (11) interposing the concentric gasket (10) on the appliance, fitting it with the screws

(12).

3. Mount the ducting system as described in the relative instructions sheet.

4. Calculate the distances between the appliance drain and the bend of the ducting system.

5. Prepare the appliance flue system, making sure that the internal pipe of the concentric kit is fitted up to the end stop in the ducting

system curve (Quota "X" Fig. 31), whereas the external pipe must reach the end stop of the adapter (1).

6. Mount the cover (A) complete with adaptor (1) and caps (6) on the wall.

7. Assemble the flue system to the ducting system.

Once all components have been assembled properly, the exhaust flue gas will be expelled via the ducting system; the combustion air for

normal boiler operation will be aspirated directly by the shaft (Fig. 31).

C

83

C

S

A

28

Key (Fig. 28):

A - Intake

C

- Minimum gradient 1.5 %

S - Exhaust

A

B

A

C

29

Ducting

ADAPTOR

(A) mm

SHAFT

(B) mm

SHAFT

(C) mm

Ø 60

Rigid

66

106

126

Ø 50

Flexible

66

106

126

Ø 80

Rigid

86

126

146

Ø 80

Flexible

103

143

163