49

Inspections and maintenance

We urge you to have authorised company fulfil

requirements regarding periodic maintenance

checks

.

Since dust is extracted from the inside, the resistance on the flue side,

through the boiler, will increase, leading to a decrease in the heat load

(and, consequentially, in the power).

Prior to cleaning, check the heat load (see parag. 3.24) and the

percentage of CO

2

(see parag. 3.24). If the measured load (with a correct

CO

2

level) is within 5% of the value indicated in parag. 3.24, the boiler

does not need to be cleaned.

The operation must therefore be limited to cleaning the trap.

ATTENTION!

A drop in the heat load can be caused by an obstruction

in the exhaust channel or air intake pipe. First of all

make sure that this is not the cause.

If there is a drop in the heat load greater than 5%, check

how clean the burner condensate-collection pan is. Also

clean the trap.

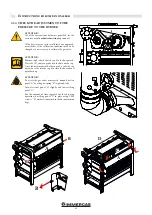

First phase – Disassembly.

- Shut off the electrical and gas supplies

making sure the valve is firmly

shut.

- Take out: all of the casings.

- Turn the required screw to lift the cover.

- Take out the two cover clamping screws.

- Act on the two rear closing hinges to take out the cover.

- Take out the rear, front and side casing clamping screws.