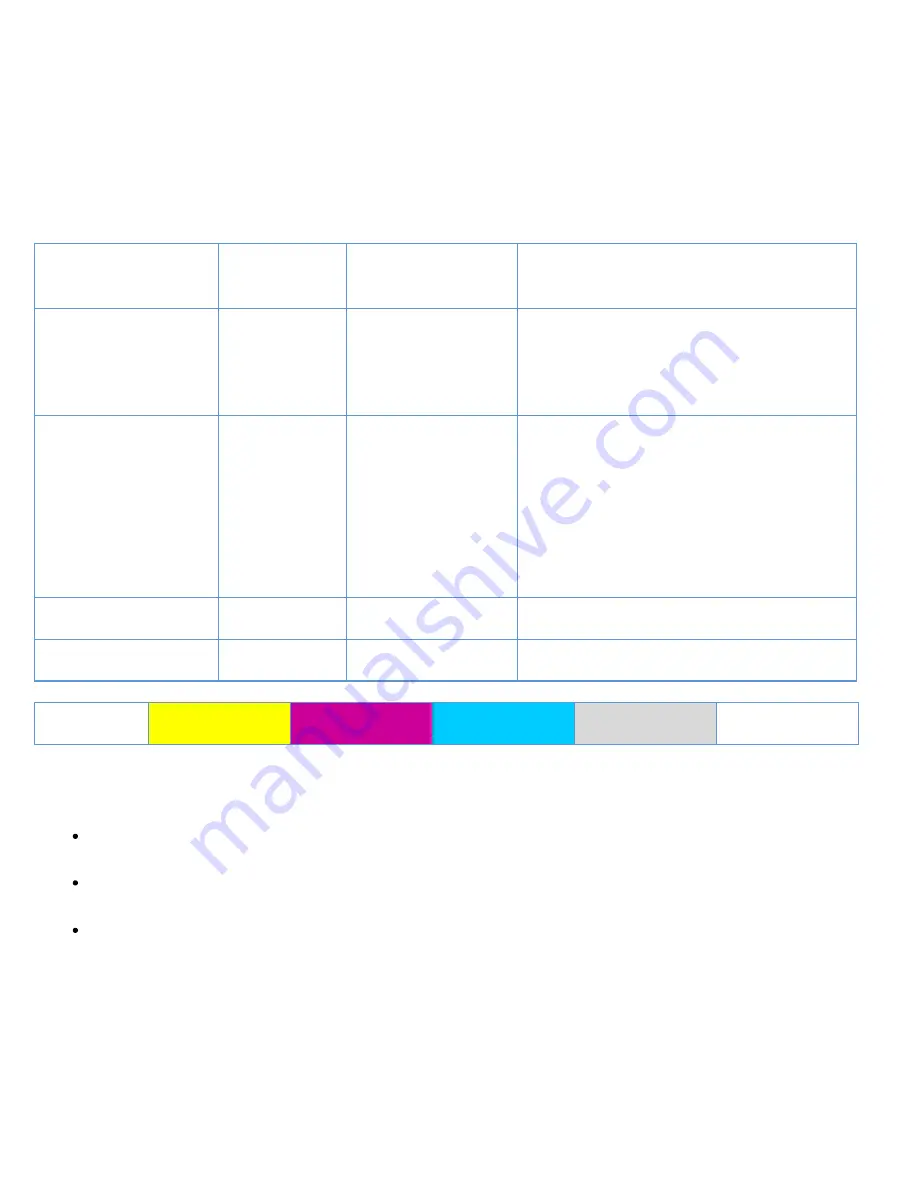

Dye Film Part Number

Film Panel

Layout

Print Capacity

(Cards)

Typical Images

MC300YMCKO/2,3

YMCKO

300

(

Prin

�

ng colour

one side only

)

.

Single Sided

Colour Side 1 only

Duple

x

Colour Side 1 & 2

MC1000K-n (n = colour)

K

1000

(

Prin

�

ng on one

side only

)

.

Single Sided Monochrome

Black

R

ed

Blue

Green

Silver

Gold

White

Scratch

MC600KO

KO

600

(

Prin

�

ng on one

side only

)

.

Single Sided

Black + Overcoat

MC250YMCKOK/2,3

YMCKOK

250

(

Prin

�

ng on both

sides of card

)

.

Duple

x

Prin

�

ng on 2 Sides.

Film Panel

Key:

Yellow (Y)

Magenta (M)

Cyan (C)

Resin (K)

black

Overcoat (O)

clear

ID Card Printer - User Manual

24

CHOOSING THE CORRECT DYE FILM:

Below is a general guide to selec�ng the most suitable film for any typical applica�on. “Scratch” film lays down a so�

film on the card’s surface which can be easily removed by light scrapping.

NOTE:

300YMCKO dye film is generally the appropriate choice for color prin�ng with both single and double-sided

(duplex) printers

.

250YMCKOK dye film is generally preferred for duplex models only as this is more economic when prin�ng color

on side 1 and monochrome on side 2.

1000K and 600KO dye film is o�en used where cost is an important factor.