71

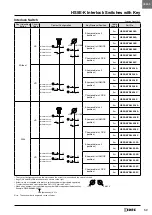

HS5E-K Interlock Switches with Key

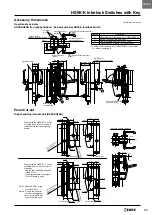

Example 2: Partial Mode Change (Multiple Robots)

Three FS1A safety controllers are required for two robots and four FS1A safety controllers for three robots .

Turn the key selector switch of the first robot (logic no . 103) to Teach Mode and remove the key . Unlock the HS5E-K interlock

switch using the same key and open the door to enter . Using the same key, Turn the key selector switches of the second

(logic No . 13b) or subsequent robots to be operated to Teach Mode . Gripping the enabling switch in the enabling position

enables the robot to operate .

Note 1: Teaching is possible with one robot at a time . Teaching multiple robots is not possible at the same time .

Note 2: The emergency stop switch connected to the first FS1A safety controller is effective for all robots .

Note 3: Connect safety outputs Y2 and Y3 (solid state outputs) of the first FS1A safety controller to the RF1V force guided relay (K1, K2), and connect its NO

contact to the safety output Y0, Y1 of the second and the subsequent FS1A safety controllers . Connect NC contact to the EDM input of the first FS1A

safety controller .

The required number of RF1V (K1, K2):

For two robots: 2NO2NC

For three robots: 3NO1NC

For four robots: 4NO2NC

Note 4: The emergency stop switch connected to the second and subsequent FS1A safety controllers are effective for the robot only .

Note 5: Connect the NC contacts of K3 and K4 to EDM input of the second FS1A safety controller . Connect the NC contacts of K5 and K6 to the EDM input of

the third FS1A safety controller . Select force guided relays for K3, K4, K5 and K6 according to the operation control circuits of the robots .

Teach Mode

Auto Mode

Y0

Y1

EDM

&

&

Self-hold function circuit 2

Self-hold function circuit 1

OSSD

OSSD

FS1A-C11S LOGIC 13b (inside the guard)

Control

&

FS1A-C11S

LOGIC103

Teach Mode

Auto Mode

Y0

Y1

EDM

&

&

Self-hold function circuit 2

Self-hold

function circuit 3

Self-hold function circuit 1

FS1A-C11S LOGIC 13b (inside the guard)

Control

&

Y2

Y0 Y1

&

Self-hold function circuit 2

EDM

&

&

Self-hold function circuit 1

Self-hold

function circuit 3

Self-hold

function circuit 3

Open

Open

K1

K2

K3

K4

K5

K6

K1

K2

K1

K2

Dual Channel

Direct Opening

Monitor Input

Dual Channel

Dependent

Dual Channel

Dependent

Dual Channel

Dependent

Dual Channel

Direct Opening

Dual Channel

Direct Opening

Monitor Input

Monitor Input

Monitor Input

Monitor Input

Monitor Input

Dual Channel

Safety

Dual Channel

Safety

External

Device

Monitor

External

Device

Monitor

External

Device

Monitor

Mode

Select II

Mode

Select

Mode

Select

Control

Start

>=1

>=1

>=1

Hold

Trigger

Self-hold

Function

Self-hold

Function

Self-hold

Function

Self-hold

Function

Self-hold

Function

Self-hold

Function

Self-hold

Function

Self-hold

Function

Self-hold

Function

Hold

Trigger

Hold

Trigger

Hold

Trigger

Hold

Trigger

Hold

Trigger

Hold

Trigger

Hold

Trigger

Hold

Control

Start

Trigger

Hold

Hold

Hold

Hold

EDM

EDM

EDM

EDM

OSSD

with

off-delay

OSSD

with

off-delay

Y3

Teach Mode

Auto Mode

HE2G

Grip Switch

HE2G

Grip Switch

HW series

Key Selector

Switch

(pin tumbler key)

Emergency

Stop Switch

Emergency

Stop Switch

Emergency

Stop Switch

HW series

Key Selector

Switch

(pin tumbler key)

HW series

Key Selector

Switch

(pin tumbler key)

HS5E-K

Key

Interlock

Switch

K1 to K6: RF1V force guided relay

HS5E-K