20

iMAT 31IFBI-24VDC

A

Angle nozzle 16

B

Blows off 18

C

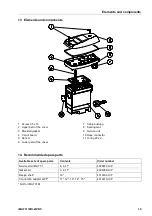

Circuit board 19

Circuit board defective 18

Components 19

Condensate discharge disturbed 18

Control 15

Control unit 16

D

Danger compressed air 4, 10, 15

Data 7

Deflector area 12

Degree of protection 5

Dimension drawing 8

Dimensions 8

E

Electric diagram 14

Electrical data 7

Electrical installation 13

Elements 19

Exclusion from the scope of application 6

Exclusion of a field of application 6

F

Failure 18

Fault clearance 18

Fault diagnosis 18

Fault elimination 18

Feed pipe 12

Field of application 6

Filling level 9

Function 9

H

Hose connector 19

I

Inlet line 9

Installation 10

Installation and operating instructions 4

Installations- und Betriebsanleitung 4

Instructions, safety instructions 4

L

Lower part of the cover 19

M

Maintenance 15

Maintenance recommendation 16

Malfunction 18

Membrane 9

Mounting 10

N

No condensate discharge 18

No function 18

No sensor signal 18

O

Order number 19

Outlet line 9

P

Piktogramme 4

Pilot valve 9

Pressure differences 12

Proper use 6

Protective extra-low voltage 14

R

Recommended spare parts 19

S

Safety instructions 4

Sensor 19

Sensor tube plate 17

Service measures 4, 10, 15

Service unit 19

Service-Unit 16

Sets of spare parts 19

Slope 12

Spare parts 5, 19

Symbole 4

Symptoms 18

T

Technical data 7

Transistor open 14, 18

Troubleshooting 18

U

Upper part of the cover 19

V

Venting line 12

W

Water pocket 12

Содержание IMAT 31IFBI-24VDC

Страница 21: ...iMAT 31IFBI 24VDC 21 ...

Страница 22: ...22 iMAT 31IFBI 24VDC ...

Страница 23: ...iMAT 31IFBI 24VDC 23 ...