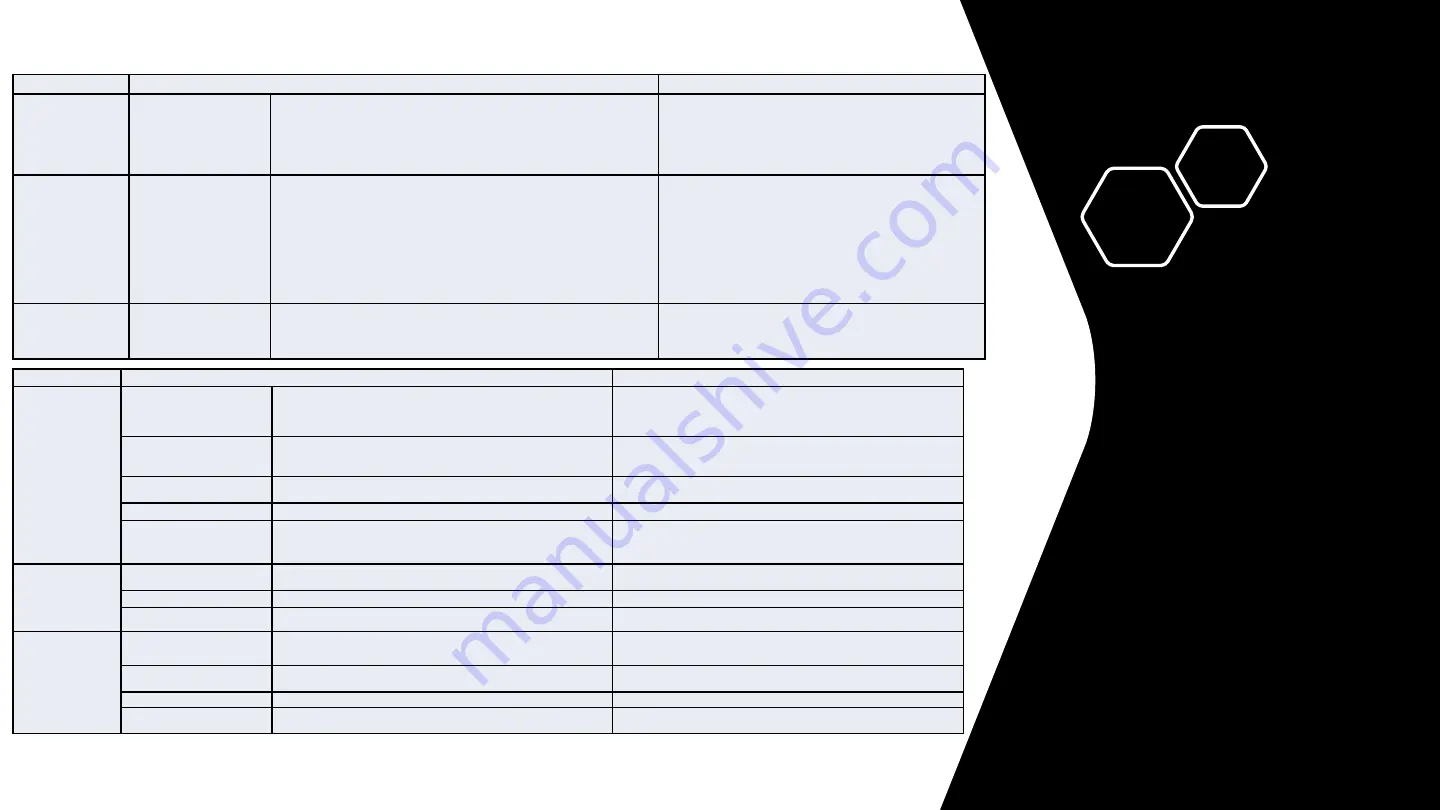

Service Fault Diagnosis

Operating status

What to check

Action

Low ice yield

1) Refrigerant

1) Is there a refrigerant leak?

2) Is the refrigerant line blocked?

3) Is the refrigerant under/overcharged?

1) Check for leaks with a leak detector, repair the

leak and replace the dryer, evacuate and

charge with refrigerant.

2) Replace any clogged parts.

3) Recover, evacuate, and recharge with refrigerant.

2) High-side pressure

is too high

1) Is the condenser and/or filter dirty?

2) Is the ambient or water temperature too high?

3) Is the condenser fan not spinning, slow, or have a broken

fan blade? (Air-cooled)

1) Clean the air filter and/or condenser.

2) Place machine in cooler environment and check

the water supply.

3) Replace the fan motor or fan blade after

determining which is the issue.

3) Expansion valve

(TXV)

1) Is the low-side pressure too low or too high?

1) Replace if stuck open or closed.

2) Check that the bulb on the expansion valve is

properly installed and replace it if necessary.

Operating status

What to check

Action

Abnormal noise

1) Fan motor

1) Are the bearings worn?

2) Is the fan blade deformed or broken?

3) Is fan blade hitting the shroud?

1) Replace motor.

2) Replace fan blade.

3) Check alignment and/or replace fan blade.

2) Compressor

1) Is the bearing worn or the cylinder valve broken?

2) Is the rubber bushing assembled correctly?

1) Replace compressor.

2) Readjust the bushing assembly position.

3) Refrigeration Line

1) Is it caused by contact with refrigerant line components?

3) Realign or replace if necessary.

4) Gear Box

1) Are the bearings or gears worn and damaged?

1) Replace gear box.

5) Evaporator

1) Are the auger bearings worn out?

2) Is there a scale inside the evaporator cylinder?

1) Check & replace if necessary.

2) Disassemble the auger and related parts, descale and

clean with descaling agent. (Periodically)

Water overflow

from the

sump(Overflow)

1) Water supply

1) Is the water supply pressure too high (above 80psi)?

1) Install a water pressure reducing valve.

2) Water supply valve

1) Does the water inlet solenoid valve close?

1) Clean or replace the valve.

3) Water level sensor

1) Is connection bad or is the sensor reading properly?

1) Check the connections and replace if defective.

Gear Motor

'MOTOR ERROR'

flashes frequently

1) Power supply

1) Is the voltage too high or too low?

1) Connect the power to the rated voltage.

2) Ice making unit

1) Are the bearings (E-Head and Housing) or Auger worn?

1) Replace bearing or auger.

3) Tachometer

1) Is motor rotation bad?

1) Check the capacitor. 2) Replace the gear motor.

1) Check the capacitor. 2) Replace the gear motor.

4) Gear Motor or Gearbox 1) Is the motor or gearbox rotation bad?

24

Содержание ID-0300-AN

Страница 1: ...ID 0300 AN INSTALL SERVICE MANUAL...

Страница 2: ...ID 0300 Specs 2...

Страница 3: ...ID 0300 Specs Water drain connections are underneath the dispenser 3...

Страница 16: ...Wiring Diagram 16...

Страница 41: ...Parts Breakdown ID 0300 41...

Страница 42: ...Parts Breakdown ID 0300 42...

Страница 43: ...Parts Breakdown ID 0300 43...

Страница 44: ...Parts Breakdown ID 0300 44...

Страница 45: ...Thank You 1 15 2022...