INSTALLATION AND OPERATION INSTRUCTIONS

1-24

DC SERIES BOILERS / WATER HEATERS

DC 15-95, DC 15-96, DC 20-125, DC 33-160

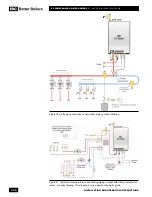

1.6.2 Basic Heating Piping Arrangements

PRIMARY / SECONDARY PIPING - BENEFITS AND INSTALLATION RULES

1.

Good circulating water flow through the boiler irrespective of load or radiation

system head

2.

Allows flexible ΔT° control in secondary loops

3.

Adds to the system’s thermal buffering, to assist in handling small loads and

temperature transition.

A Primary / Secondary piping configuration requires an extra pump, independant

from any secondary load pumps. The DC series modulating boiler / water heater

includes the boiler Primary Pump installed inside the boiler / water heater cabinet

and is pre-wired. The pump’s volute is epoxy coated to allow compatibility with

the non-oxygen barrier tubing found in some older radiant heating systems.

For optimal performance, place pumps on the supply side of secondary loops

to facilitate air evacuation. Use pumps with internal check valves to avoid ghost

flows and thermal siphoning.

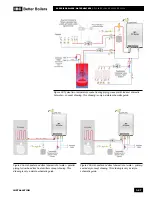

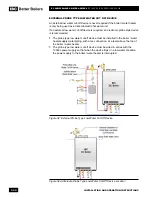

The DC series boilers are designed to be piped in a Primary/Secondary piping

arrangement. In some cases the boiler can be piped in series with the heating

load if the boiler’s pump is capable of providing the flow and head the system

requires. For example a DC series boiler and an IBC Air Handler series can

be installed together without the use of an additional pump if the air handler is

installed within close proximity of the boiler and with properly sized supply and

return piping (

see Figure 29a

).

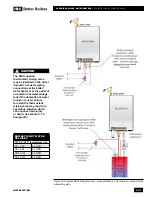

Propylene Glycol mixtures of 25% - 50% are acceptable for use within the

boiler and piping system. In general, the use of propylene glycol will reduce the

heating capacity of the heating system and increases the pump head required for

adequate boiler / water heater flow.

If the installation involves small loads, as in typical zoned baseboard heating

applications, use of a buffer tank is recommended. To aid in temperature

transition from hot to cool loads, a 3-way mixing valve can be placed at the

entrance to the cool load (this will also provide floor protection). This will permit

immediate circulation of mixed flow into the cool loop

.

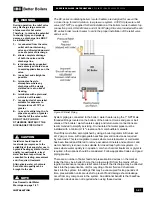

1.6.3 Boiler Pump Air Bleeding

After filling the boiler for the first time, bleed any air trapped in the boiler pump.

An absorbent cloth should be placed beneath the large slotted screw in the

center of the pump. Turn this screw counter-clockwise until water drips from

behind it and air is purged. Reseal the screw, but do not over-tighten.

WARNING

Do not use automotive-

type ethylene or other

types of automotive glycol

antifreeze, or undiluted

antifreeze of any kind. This

may result in severe boiler

/ water heater damage. It

is the responsibility of the

Installer to ensure that glycol

solutions are formulated to

inhibit corrosion in hydronic

heating systems of mixed

materials. Improper mixtures

and chemical additives may

cause damage to ferrous and

non-ferrous components as

well as non-metallic, wetted

components, normally found

in hydronic systems. Ethylene

glycol is toxic, and may be

prohibited for use by codes

applicable to your installation

location. For environmental

and toxicity reasons, IBC

recommends only using non-

toxic propylene glycol.

Содержание DC Series

Страница 78: ...NOTES...

Страница 79: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...