6. Test and Finish the Installation

Once you have installed both the control head and the transom transducer, and

have routed all the cables, you must perform a final test before locking the

transducer in place. Testing should be performed with the boat in the water,

although you can initially confirm basic operation with the boat out of the water.

1. Press POWER once to turn the control head on. If the unit does not

power up, make sure that the connector holder is fully seated in the

receptacle and that power is available.

2. If all connections are correct and power is available, the

Humminbird® control head will enter Normal operation.

3. If the bottom is visible on-screen with a digital depth readout, the unit

is working properly. Make sure that the boat is in water greater than 2'

but less than the depth capability of the unit, and that the transducer

is fully submerged, since the sonar signal cannot pass through air.

NOTE:

The transducer must be submerged in water for reliable transducer

detection.

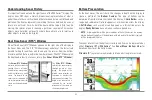

4. If the unit is working properly, gradually increase the boat speed to

test high-speed performance. If the unit functions well at low

speeds, but begins to skip or miss the bottom at higher speeds, the

transducer requires adjustment.

5. If you have the correct angle set on the transducer, yet lose a bottom

reading at high speed, adjust the height and the running angle in

small increments to give you the ideal transducer position for your

boat. First, adjust the height in small increment.

NOTE:

The deeper the transducer is in the water, the more likely that a rooster

tail of spray will be generated at high speeds, so make sure that the transducer

is as high as it can be and still be submerged in the water.

If you are still not getting good high speed readings, you may need

to disassemble the transducer mounting assembly and re-position

the ratchets.

If you do change the transducer position, re-trace the position of the

mounting bracket before proceeding.

NOTE:

It is often necessary to make several incremental transducer adjustments

before optimum high speed performance is achieved. Due to the wide variety of boat

hulls, however, it is not always possible to obtain high speed depth readings.

6. Once you have reached a consistently good sonar signal at the

desired speeds, you are ready to lock down the transducer settings.

Force the pivot to the Up position to gain access to the mounting

screws, then re-align the mounting bracket against the transom of

the boat to match the traced silhouette. Check the bracket position

with the level again to make sure it is still level, then mark the third

mounting hole using a pencil or marker. Unscrew and remove the

mounting screws and the transducer assembly and set aside.

7. Drill the third mounting hole, using a 5/32” drill bit. Use a marine-

grade silicone sealant to fill all three drilled mounting holes,

especially if the holes penetrated the transom wall.

NOTE:

On fiberglass hulls, it is best to use progressively larger drill bits to reduce

the chance of chipping or flaking the outer coating.

20