62

LP-171 Rev. 3.3.15

To adjust, press either

{S1}

(Decrease Value) or

{S2}

(Increase Value) Ranges 5°F to 30°F. Press

{S3}

again and you will see the

Indirect Setting de and an alternative value of 119 (

with Vision Systems option

). To adjust, press either

{S1}

(Decrease Value) or

{S2}

(Increase Value).

The final adjustment in this mode is the Fahrenheit to Celsius measurement. Press

{S3}

again and you will see t and alternating value

of F. To change value, press

{S1}

or

{S2}

to choose the correct measurement.

C. STATUS MENU

Installers are also able to check the current status of heater parameters by pressing

{S4}

for 3 seconds. Once activated, the display will

show

|d1|

alternating value of the actual outlet temperature. Actual values are displayed for each function. To view the next value, press

{S4}

to go to the next displayed value. Listed below are the values which can be displayed. These values cannot be changed. To exit

this menu, simply press

{S3}

to resume normal operation.

Function

Value

d1

— Actual Temperature from outlet sensor

d2

— Actual Temperature from inlet sensor

d3

— If using a standard mechanical control, the control will display

|1|

for closed

|0|

for open. If the sensor is connected to the

SuperStor Indirect Fired Water Heater it will measure the actual temperature (Vision option).

Function

Value

d4

— Not used

d5

— Actual Temperature from the outdoor sensor (Vision option).

d6

— Actual Fan speed multiplied by 10 (Example: If fan speed displayed is

|410|

RPM x 10 = 4100 actual fan speed)

d7

— Actual Ionization current read from Flame Rectification probe

d8

— Actual Status of the Central Heating Circulator Off =

|0|

, On =

|1|

. (Vision option.)

d9

— Actual Status of the Indirect Fired Circulator Off =

|0|

, On =

|1|

. (Vision option.)

d10

— Actual Status bus communication

|co|

= connected,

|no|

= not connected

d11

— Central Heating Set Point

d12

— Power On Hours in units

d13

— Total Central Heat Hours

d14

— Total Indirect/dhw Hours

d15

— Passed Ignition Attempts

D. TEST MODE

This function is intended to simplify the gas valve adjustment if needed. Listed below are the recommended limits on each heater and

the combustion settings. Automatic modulation does not take place when the controller is in Test mode, only temperature limitation

based on the heater central heating set point. The user will be allowed to increase or decrease the fan speed by pressing in either

{S1}

or

{S2}

.

To activate Test mode, press

{S2}

and

{S3}

together for 1 second. Once activated, you will see

{Ser}

in the display and the actual fan

speed. The measurement of the combustion levels should always be taken at the highest and lowest fan speed. After 10 minutes, the

Test mode stops automatically. To exit Test mode, press

{S1}

and

{S2}

together for 1 second.

COMBUSTION SETTINGS ON ALL MODELS

Natural Gas

Propane LP

Fan Speed

Low

Ignition

High

Low

Ignition

High

Carbon Monoxide PPM

5

– 50

60

– 100

< 150

5

– 50

60 - 140

< 150

Carbon Dioxide (CO

2

)

8 - 10%

8 ½

– 10 ½%

8 ½ - 10 ½%

9 - 10 ½%

9 - 11%

Table 9

FAN SPEEDS

HEATER

HIGH

LOW

IGNITION

MC-50

3300

1250

3000

MC-80

4250

1200

4250

MC-99

4700

1500

3000

MC-120

5500

1500

3000

Table 10

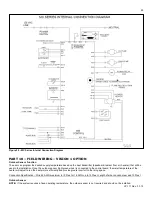

PART 13 – START-UP PROCEDURES WITH VISION 1 OPTION

The Vision I option allows the user to have one temperature for central heating and another temperature for the SuperStor Ultra Indirect

Fired Water Heater. This enables the user to increase the temperature supplied to the indirect water heater by prioritizing flow at a

higher temperature than may be needed for the central heating circuits (this will require two separate circulators). Once the indirect

Содержание MC120

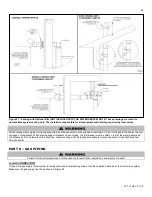

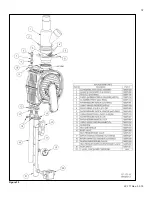

Страница 21: ...21 LP 171 Rev 3 3 15 M PIPING DETAILS Figure 5 ...

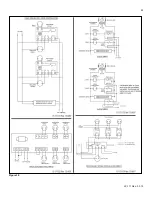

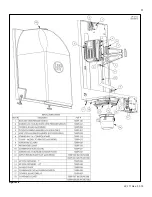

Страница 53: ...53 LP 171 Rev 3 3 15 Figure 30 ...

Страница 71: ...71 LP 171 Rev 3 3 15 Figure 34 ...

Страница 72: ...72 LP 171 Rev 3 3 15 Figure 35 ...

Страница 73: ...73 LP 171 Rev 3 3 15 Figure 36 ...

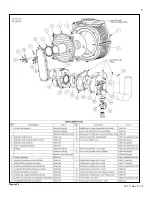

Страница 76: ...76 LP 171 Rev 3 3 15 ...

Страница 77: ...77 LP 171 Rev 3 3 15 ...

Страница 78: ...78 LP 171 Rev 3 3 15 MAINTENANCE NOTES ...