58

LP-171 Rev. 3.3.15

B. FREEZE PROTECTION (WHEN USED)

NEVER use automotive or standard glycol antifreeze, or ethylene glycol made for hydronic systems. System water, including additives,

must be non-toxic, having a toxicity rating or Class of 1, as listed in Clinical Toxicology of Commercial Products. Use only freeze-

prevention fluids certified by fluid manufacturer as suitable for use with stainless steel heaters, verified in fluid manufacturer literature.

Thoroughly clean and flush any system that has used glycol before installing the new heater. Provide heater owner with a material

safety data sheet (MSDS) on the fluid used.

1. Determine freeze protection fluid qua

ntity using total system water content, following fluid manufacturer’s instructions. Remember to

include expansion tank water content.

2.

NOTE:

Local codes may require back flow preventer or actual disconnect from city water supply.

3. When using freeze protection fluid with automatic fill, install a water meter to monitor water makeup. Freeze protection fluid may leak

before the water begins to leak, causing concentration to drop, reducing the freeze protection level.

C. FILL AND TEST WATER SYSTEM

Ensure the heater is full of water before firing the burner. Failure to do so will damage the heater. Such damage IS NOT covered by

warranty, and could result in property damage, severe personal injury, or death.

1. Fill system only after ensuring the water meets the requirements of this manual.

2. Close manual and automatic air vents and heater drain valve.

3. Fill to correct system pressure. Correct pressure will vary with each application.

a. Typical cold water fill pressure for a residential system is 12 psi.

b. Pressure will rise when heater is turned on and system water temperature increases. Operating pressure must never

exceed 25 psig.

4. At initial fill and during heater startup and testing, check system thoroughly for any leaks. Repair all leaks before proceeding further.

Eliminate all system leaks. Continual fresh make-up water will reduce heater life. Minerals can build up in the heat exchanger, reducing

heat transfer, overheating heat exchanger, causing heat exchanger failure, and possibly resulting in property damage, severe personal

injury, or death.

5. The system may have residual substances that could affect water chemistry. After the system has been filled and leak tested, verify

water pH and chlorine concentrations are acceptable.

D. AIR PURGING PROCEDURE FOR HEAT EXCHANGER

It is important that you purge the system of air to avoid damage to the heater. Make sure that this procedure is followed before firing the

heater.

The heater must be room temperature before attempting to purge air from the heat exchanger purge valve. The supplied tubing is rated

to 120

o

F maximum.

The control system allows the installer to run the heater pump and indirect pump manually to assist in purging air from the system. This

feature, in combination with the supplied purge hose and fitting on the heat exchanger, will help to remove air from the heat exchanger

and hydronic piping system.

To remove air from the system, follow the steps listed on the following page:

Open manual air vent BY HAND ONLY! Use of tools, such as wrenches or pliers, can snap or crack the valve.

NOTE: This damage

IS

NOT COVERED BY WARRANTY!

Содержание MC120

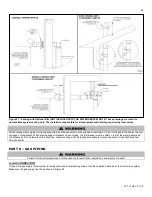

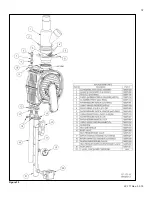

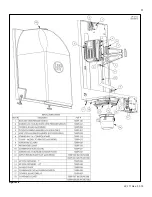

Страница 21: ...21 LP 171 Rev 3 3 15 M PIPING DETAILS Figure 5 ...

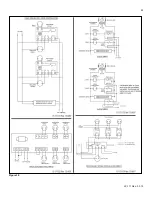

Страница 53: ...53 LP 171 Rev 3 3 15 Figure 30 ...

Страница 71: ...71 LP 171 Rev 3 3 15 Figure 34 ...

Страница 72: ...72 LP 171 Rev 3 3 15 Figure 35 ...

Страница 73: ...73 LP 171 Rev 3 3 15 Figure 36 ...

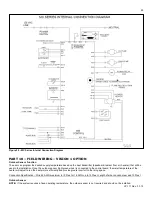

Страница 76: ...76 LP 171 Rev 3 3 15 ...

Страница 77: ...77 LP 171 Rev 3 3 15 ...

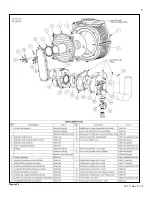

Страница 78: ...78 LP 171 Rev 3 3 15 MAINTENANCE NOTES ...