VR8245 AND VR8345 UNIVERSAL ELECTRONIC IGNITION GAS CONTROLS

3

69-2013

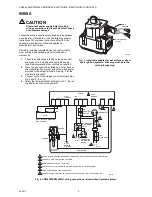

CAUTION

Never apply a jumper across or short the valve

coil terminals. This can burn out the heat

anticipator in the thermostat or damage the

electronic intermittent pilot (IP) module.

IMPORTANT:

These gas controls are shipped with protective

seals over inlet and outlet tappings. Do not

remove seals until ready to connect piping.

Follow the appliance manufacturer instructions if

available; otherwise, use the following instructions.

Converting Between Natural And LP Gas

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH

Do not attempt to use a gas control set for natural

gas on LP gas or a gas control set for LP gas on

natural gas.

Convert standard-opening gas controls from natural gas

to LP gas with the conversion kit included with this

TRADELINE® gas control. For conversion kit part

number, see Table 3.

Use Pipe Adapter to Solve Swing Radius

Problems

In some field service applications, space limitations make

it difficult or impossible to thread the gas control onto the

gas supply pipe. This problem can be resolved for many

installations by using a pipe adapter. Install the pipe

adapter on the end of the supply pipe in place of the gas

control by following the same precautions and instructions

that are used for installing the gas control. After the pipe

adapter is installed, attach the gas control to the adapter

as outlined in the Install Pipe Adapters to Gas Control

section.

NOTE: Using a pipe adapter increases the overall length

of the gas control.

Install Pipe Adapter to Gas Control

Install adapter to gas control as follows:

Bushings

1.

Remove seal over gas control inlet or outlet.

2.

Apply moderate amount of good quality pipe com-

pound to bushing, leaving two end threads bare.

See Fig. 1.

3.

Insert bushing in gas control and carefully thread

pipe into the bushing until tight.

Fig. 1. Use moderate amount of pipe compound.

Location

Locate the combination gas control in the appliance

vestibule on the gas manifold. In replacement

applications, locate the gas control in the same location

as the old control.

Do not locate the gas control where it can be affected by

steam cleaning, high humidity, dripping water, corrosive

chemicals, dust or grease accumulation, or excessive

heat.

For proper operation, follow these guidelines:

• Locate gas control in a well-ventilated area.

• Mount gas control high enough above the cabinet

bottom to avoid exposure to flooding or splashing

water.

• Make sure the ambient temperature does not exceed

the ambient temperature ratings for each component.

• Cover gas control when the appliance is cleaned with

water, steam, or chemicals or to avoid dust and grease

accumulation.

• Avoid locating gas control where exposure to corrosive

chemical fumes or dripping water is possible.

Install Piping to Gas Control

All piping must comply with applicable codes and

ordinances or with the National Fuel Gas Code (ANSI

Z223.1 NFPA No. 54), whichever applies. Tubing

installation must comply with approved standards and

practices.

VR8345Q4563

VR8205Q2555

36E54-214, 36G54-214

VR8304Q4511

36C76-406, 36C76-420,

36C76-463

VR8305Q4146, VR8305Q4500 36D13-208, 36D13-405

36E96-314,

720-082 (7200IPER2-4)

Table 4. Cross Reference. (Continued)

Universal

Replacement

Cross Reference

Universal

Service Part

Honeywell

White-Rodgers

Robert-Shaw

TWO IMPERFECT

THREADS

GAS CONTROL

THREAD PIPE THE AMOUNT

SHOWN IN TABLE FOR

INSERTION INTO GAS CONTROL

APPLY A MODERATE AMOUNT OF

PIPE COMPOUND TO PIPE ONLY

(LEAVE TWO END THREADS BARE).

M3075B

PIPE