UV100E ULTRAVIOLET SYSTEMS

68-0262—5

10

10.

For Air Treatment Systems, wait ten minutes for the

airflow sensor to calibrate. During this time, the furnace

fan must remain off.

NOTE: Failure to wait ten minutes for the airflow sensor to

calibrate before powering the system fan causes the

airflow sensor to incorrectly calibrate and the device

to incorrectly function. If this occurs, remove power to

the furnace or turn off the system fan, wait ten

minutes, and then resume normal fan operation.

11.

Verify that ultraviolet lamp is operating by viewing only

through the lamp light indicator on the lamp handle.

Never look directly at your bulbs while illuminated

.

12.

Reconnect power to your heating and cooling system.

CAUTION

UV Lamp Burn Hazard.

Harmful to bare skin.

Can cause severe burns.

Disconnect power 15 minutes before removing

ultraviolet bulb(s).

Bulb Replacement

Replacement of the bulb in your ultraviolet lamp when the LED

is solidly lighted is required to maintain effectiveness.

1.

Obtain the correct replacement bulb for your unit. See

Table 1.

2.

Disconnect power to your heating and cooling system.

3.

Unplug or turn off power to your UV System and allow

the lamp to cool for at least 15 minutes.

4.

Rotate the lamp handle counterclockwise and gently pull

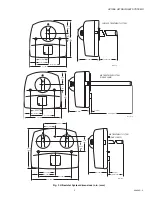

the lamp handle to remove the bulb(s). See Fig. 11.

5.

If you have a SnapLamp™ handle, follow steps 5 and 6;

otherwise, proceed to step 7. Grasp the SnapLamp™

handle in one hand and the lamp glass in the other and

pull straight apart. See Fig. 16.

Fig. 16. Disconnect lamp glass from SnapLamp™ handle.

6.

Insert the new lamp glass into the SnapLamp™ handle

by aligning the notch and pushing straight together. See

Fig. 17.

Fig. 17. Replace lamp glass in SnapLamp™ handle.

7.

Insert the lamp handle into the base with the lamp light

indicator at the eleven o’clock position. Continue pushing

and gently rotating counterclockwise until the lamp

handle inserts fully into the base. See Fig 4.

8.

Rotate the lamp clockwise until it snaps into place with

the lamp light indicator aligned with the raised button on

the unit cover. See Fig. 6.

9.

Reconnect power to your UV System.

10.

For UV Air Treatment Systems, wait ten minutes for the

airflow sensor to calibrate. During this time, the furnace

fan must remain off.

NOTE: Failure to wait ten minutes for the airflow sensor to

calibrate before powering the system fan causes the

airflow sensor to incorrectly calibrate and the device

to incorrectly function. If this occurs, remove power to

the furnace or turn off the system fan, wait ten

minutes, and then resume normal fan operation.

WARNING

UV Light Hazard.

Harmful to bare skin and eyes.

Can cause temporary or permanent loss of vision.

Never look at bulbs while illuminated.

View illumination only through lamp light indicator

located on lamp handle.

To prevent exposure to ultraviolet light, disconnect

power to ultraviolet system before servicing any part of

heating and air conditioning system.

11.

Verify that your ultraviolet lamp is operating by viewing

only through the lamp light indicator on the lamp handle.

Never look directly at your bulb while it is illuminated.

12.

Reconnect power to your heating and cooling system.

13.

Press and hold the reset button for five seconds to reset

the internal timers.

Table 1. Select a Replacement Bulb/Handle Assembly

or Replacement Bulb.

Unit Description

Replacement

Bulb/Handle

Assembly

SnapLamp™

Replacement

Bulb

UV100E1043

Air Treatment System

UC100E1006

UC18W1004

UV100E2009

Air Treatment System

UC100E1030

(two required)

UC36W1006

(two required)

UV100E3007

Surface Treatment

System

UC100E1030

UC36W1006

M22851

M22853

Содержание UV100E series

Страница 15: ...UV100E ULTRAVIOLET SYSTEMS 15 68 0262 5 ...