UV100E ULTRAVIOLET SYSTEMS

68-0262—5

2

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1.

Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2.

Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

SPECIFICATIONS

IMPORTANT

This product is tested and calibrated under closely

controlled conditions and some minor differences in

performance can be expected if those conditions are

changed. The specifications in this publication do not

include normal manufacturing tolerances; therefore,

an individual unit may not exactly match the listed

specifications.

TRADELINE® Models available:

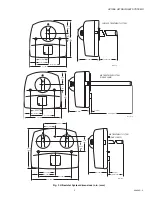

The UV100E Ultraviolet System is available in three models: a

single-lamp air treatment system, a dual-lamp air treatment

system, and a surface treatment system.

• UV100E Air Treatment Systems (single-lamp and dual-

lamp) are mounted in the return air duct of an HVAC

system. The single-lamp unit has moderate efficiency and

the dual-lamp unit has high-efficiency performance against

airborne bacteria in return air applications.

—

Without Enviracom hooked up:

monitors air flowing

through ductwork using supplied airflow sensor

mounted to backside of unit. Operates lamp when air

is flowing (120 fpm minimum), leaving lamp on for 40

minutes after airflow stops. If airflow resumes during

the 40 minutes, the timer resets to 40 minutes. When

no airflow is detected for 40 minutes, the lamp turns off

until the next occurrence of airflow.

—

With Enviracom hooked up:

monitors thermostat load

information instead of using airflow sensor to operate

on and off.

• UV100E Surface Treatment System is mounted in the

supply-side air duct or downstream or upstream from air

conditioner evaporator coils in HVAC system. It reduces

mold growth and spores on duct surfaces, coils and drip

pans.

— Does not use an airflow sensor.

—

Without Enviracom hooked up:

operates steady on/off

cycle: lamp operates three hours on, three hours off

for a total two-year life cycle.

—

With Enviracom hooked up:

after initial three hours run

time, operates three hours on and three hours off dur-

ing times when the evaporator A-coil may be exposed

to moisture, including when the control sees a cooling

call and for 30 days after the last cooling occurred.

This operation extends the bulb life beyond two years.

Efficiencies:

• UV100E Surface Treatment System: Kills up to 99.9% of

mold on system cooling coils.

— Test performed in a test duct showed reduction in col-

ony-forming aspergillus niger mold spores when sur-

face was irradiated at a distance of 18 in. for three

hours in still air, using new lamps.

• UV100E Air Treatment System (dual-lamp): Kills up to 87%

of airborne bacteria passing by the system.

— Test showed single-pass kill-rate of serratia marce-

scens bacteria in a clean metal 12 in. x 25 in. duct at

an airflow rate of 2000 cfm using new lamps.

• UV100A Air Treatment System (single-lamp): Kills up to

70% of airborne bacteria passing by the system.

— Test showed single-pass kill-rate of serratia marce-

scens bacteria in a clean metal 12 in. x 25 in. duct at

an airflow rate of 2000 cfm using new lamps.

Enviracom™ Communications Capabilities:

• Communicates with homeowner through three-wire

communication bus using 24 Vac thermostat connections.

—

Hooked up to single-lamp and dual-lamp Air Treat-

ment System:

uses thermostat load information

instead of airflow sensor.

—

Hooked up to Surface Treatment System:

uses

thermostat load information to operate during times

evaporator A-coil may be exposed to moisture to

extend bulb life beyond two years.

• Sends messages to communicate reset and receives

remote reset, when available.

— Lamp change indication cannot be reset by cycling

power.

— When Enviracom is transmitting messages, shows

flashing green Enviracom LED on bottom of unit.

Electrical Ratings:

Voltage Rating: 120 Vac, 60 Hz.

Current and Power Ratings:

Model

Input Power

(A)

Bulb Wattage

(W)

UV100E1043 Air Treatment

System (single lamp)

0.46

18

UV100E2009 Air Treatment

System (dual lamp)

0.62

36

(each bulb)

UV100E3007 Surface

Treatment System

0.74

36

Содержание UV100E series

Страница 15: ...UV100E ULTRAVIOLET SYSTEMS 15 68 0262 5 ...