UV100E ULTRAVIOLET SYSTEMS

68-0262—5

8

TROUBLESHOOTING AND SERVICE

The Ultraviolet System has no field-serviceable parts. Bulb

cleaning is recommended as routine maintenance quarterly or

every three months. Bulb replacement is required when the

LED on the front of the UV system is lighted solidly. See the

Owner’s Guide for detailed procedural information.

If systems with an airflow sensor (UV100E1043 and

UV100E2009 Air Treatment Systems), incorrectly identify

airflow, the airflow sensor may be calibrated incorrectly. To

recalibrate the sensor, remove power to the furnace or turn off

the system and fan, wait ten minutes, and then resume normal

furnace operation. Even if the lamp fails to turn off, the sensor

was recalibrated during this operation.

If the internal temperature exceeds the ballast high-

temperature limit, the control continues to retry every three

hours until the temperature is low enough to run correctly. An

Enviracom fault message (when connected) sent after 72

hours. If reset is pushed during this fault, the control tries to

restart but cannot start until temperature returns to normal.

If the bulb(s) burns out, experiences low supply voltage

(brownout) or has an internal catastrophic failure, the control

continues to retry once every hour until the problem is

corrected. An Enviracom fault message (when connected) is

sent after 24 hours. If reset is pushed during this fault, the

control tries to restart but cannot start until fault is corrected.

To determine if a bulb is burned out or other problem exists,

press the reset button briefly (one second). The bulb(s) should

come on (as indicated by the illuminating lamp light indicator).

Hold reset button longer only when replacing the bulb.

MAINTENANCE

How You Can Maintain Your UV System

You should regularly clean your ultraviolet lamp to maintain

peak effectiveness of your air treatment or surface treatment

system. Replace the ultraviolet bulb when the LED status light

on the front of your UV System is on steadily.

CAUTION

Personal Injury Hazard.

Power supply can cause electrical shock.

Disconnect power supply before cleaning or replacing

ultraviolet bulb(s).

Do not open base unit or lamp handle; there are no

user-serviceable components inside.

CAUTION

Breakable Glass Hazard.

Can cause personal injury.

Be careful when inserting bulb(s) into lamp base.

Wear protective gloves when handling bulb(s).

Quarterly Bulb Cleaning

MERCURY NOTICE

This device contains mercury (less than 5 mg) in the

sealed ultraviolet bulb(s). Do not place your used

bulb(s) in the trash. Dispose of properly.

Broken Bulb Cleanup.

Do not use a household vacuum.

Sweep debris into a plastic bag and dispose of

properly.

Contact your local waste management authority for

instructions regarding recycling and the proper disposal

of old bulb(s).

Bulb cleaning is recommended as routine maintenance

quarterly or every three months. Use the UV Bulb Cleaning

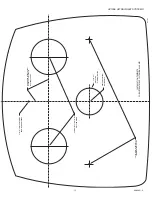

Reminder Schedule, Fig. 10, to help you establish and track

your regular cleaning schedule.

Fig. 10. UV bulb cleaning reminder schedule.

CAUTION

UV Lamp Burn Hazard.

Harmful to bare skin.

Can cause severe burns.

Disconnect power 15 minutes before removing

ultraviolet bulb(s).

To clean your bulb:

1.

Disconnect the power to your heating and cooling

system.

2.

Unplug or turn off power to your UV system and allow the

bulb to cool for at least 15 minutes.

3.

Rotate your lamp handle counterclockwise and gently

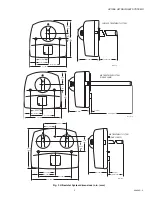

pull the lamp handle to remove the bulb(s). See Fig. 11.

YEAR

UV BULB CLEANING REMINDER SCHEDULE

, (year)

M13516A

J

F

M

A

M

J

J

A

S

O

N

D

INSTALLATION DATE: (month)

Содержание UV100E series

Страница 15: ...UV100E ULTRAVIOLET SYSTEMS 15 68 0262 5 ...