6

TP970 AND TP9600 SERIES PNEUMATIC THERMOSTATS

77-9382—1

The Thermostat provides a BLP that is a function of ambient

temperature. The force from the bimetal acting on the flapper

is balanced by the feedback force of the BLP acting on the

opposite side of the flapper through the nozzle. If the

setpoint knob is changed to a new setting, the opposing

forces in the lever system go out of balance and the room

ambient temperature changes to rebalance the lower

system.

For example, if the setpoint cam is moved to a higher

temperature setting, the point of the lever system that rides

the slope of the cam rises (reverse-acting device) due to this

cam slope. As a result, the bimetal increases its force

applied to the flapper. The increased force causes the BLP

to build up and a cooling valve to open. Cooling is introduced

to the space until the forces of the bimetal are again in

equilibrium with the opposing force (8 psi [55 kPa] times the

area of the nozzle at the flapper). A reduction in setpoint

causes the reverse to happen.

The calibration screw allows for matching the bimetal start

position with the indicated setting on the setpoint cam to

achieve an 8 psi (55 kPa) BLP at the indicated setpoint.

The TR adjustment provides a means for changing the

effective length of the bimetal. When the TR adjustment is

moved over the nozzle, the force from the bimetal is exerted

directly over the nozzle and a narrow TR, or very high

sensitivity, results. For example, a 1

°

F (0.56

°

C) change in

temperature results in a 5 psi (34 kPa) BLP change.

When the TR adjustment is moved toward the end of the

bimetal away from the nozzle, the effective force output of

the bimetal is reduced. This reduction requires a greater

temperature change at the bimetal to throttle the flapper over

the nozzle. The result is a wider TR or very low sensitivity; for

instance, a 1

°

F (0.56

°

C) change in temperature results in

only a 1 psi (7 kPa) BLP change.

TP970A-D AND TP9600A, B HIGH-

CAPACITY, SINGLE-TEMPERATURE

THERMOSTATS

General

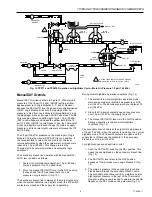

The TP970 and TP9600A, B Thermostats (Fig. 10) are the

basic TP973 with a valve unit added for greater capacity to

control valve or damper actuators in heating or cooling

systems.

TP970A, B, C, D and TP9600A, B devices are bimetal-

element, pilot-operated, two-pipe, proportioning pneumatic

Thermostats. The TP970A, C and TP9600A are direct acting

(BLP increases as temperature increases). The TP970B, D

and TP9600B are reverse-acting (BLP decreases as

temperature increases).

Fig. 10. TP970 and TP9600 High Capacity

Pilot Operated Thermostat.

NOTE:

TP970C1000 (direct acting) and TP970D1008

(reverse acting) Thermostats have extended

throttling ranges of 5 to 20

°

F (2.5 to 10

°

C) for

energy conservation applications. The extended

throttling range allows for a Zero Energy Band

(ZEB) between sequenced heating and cooling

modes.

Operation

Direct Action

Refer to Figure 11. On a temperature rise, the flapper is

forced toward the nozzle by the action of the bimetal. The

force of the bimetal acting on the flapper is balanced by the

feedback force of the pilot pressure in the nozzle chamber

acting in an opposing direction. This action varies the

flapper-nozzle gap, which in turn causes an increased

pressure in the pilot line. The change in pilot pressure is

routed to the flow amplifier that converts the low capacity

pilot pressure signal to a high capacity branchline flow at the

same pressure.

For a more detailed discussion, refer to the Valve Unit

Operation section.

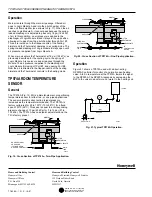

FLAPPER

THROTTLING RANGE

ADJUSTMENT

BRANCH LINE

PRESSURE GAGE PORT

BIMETAL

NOZZLE

CALIBRATION

SCREW

SETPOINT

CAM

SETPOINT

KNOB

SETPOINT KNOB

VALVE UNIT

C6055