T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

11

62-0255—07

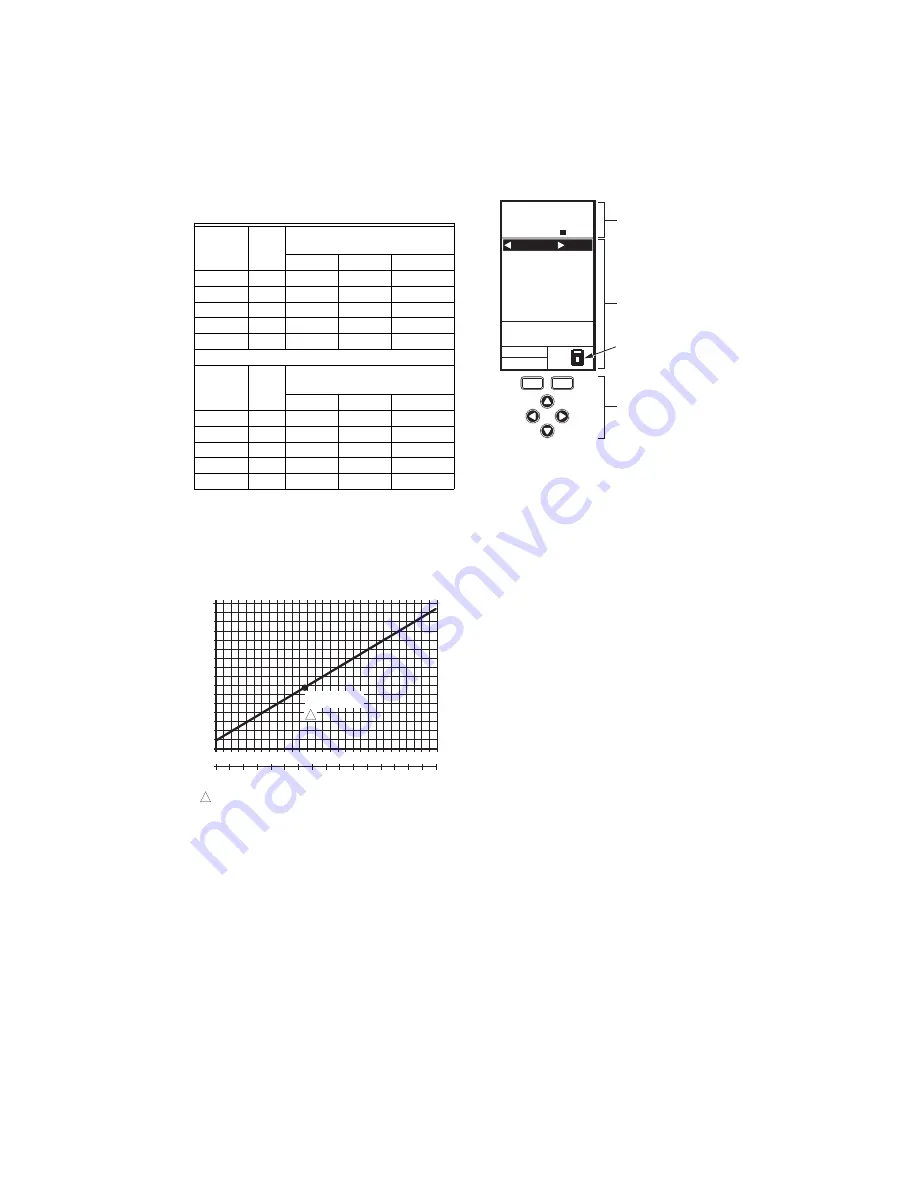

Fig. 19 shows how sensor resistance varies with

temperature for a sensor having a positive temperature

coefficient (PTC) of 2.1 Ohms per degree F (3.85 Ohms

per degree C).

Fig. 19. Sensor Resistance vs. Temperature.

INTERFACE OVERVIEW

The T775U controller uses an LCD panel and 6-button

keypad to provide status information and permit user input

of the programming, setup, and scheduling parameters.

The following figure describes the display areas of the

LCD and the keypad.

Fig. 20. LCD Display - Home Screen And Keypad.

Menu Area

– On the home screen, the LCD displays the

configured relays and whether they are active. In

Program, Setup or Schedule mode, the LCD displays the

current menu selection and its order within the menu

hierarchy.

Data Area

– On the home screen, the LCD displays the

sensors and outputs status. In Setup or Program mode,

the LCD displays menu choices, parameter selections,

and data values.

Lock Icon

– The icon indicates the MENU button is

locked and prevents access to the Setup and Program

menus.

NOTE: Pressing and holding the

HOME

and MENU but-

tons simultaneously for five seconds locks/

unlocks the MENU button.

6-Button Keypad

– The keypad is used to access the

menus and enter values (see “Using the LCD Panel

Interface”).

Using the LCD Panel Interface

The 6-button keypad is used to move through the menus

and enter or change parameter values.

Home Button

Pressing the

HOME

button at any time exits the current

Programming or Setup display screen and returns to the

home screen as shown in Fig. 20 and Fig. 21.

Menu Button

• Pressing the MENU button always displays the

Program menu. If you are in Setup mode, you exit

setup and return to the Program menu.

• Pressing and holding the MENU button for five

seconds leaves the current screen and displays

the Setup menu.

Left and Right Arrow Buttons

(

W

and

X

)

Use these buttons to move backward (

W

) and forward (

X

)

through the Program and Setup menus.

Table 4. Temperature Sensor Calibration for

Resistance Loss due to Wire Length.

AWG

Rating

m

Ω

/ft

Temperature Offset in

°F (Feet)

a

a

This is the distance from the controller to the sensor

(already accounts for round trip distance).

200 ft

500 ft

1,000 ft

14

2.5

0.46

1.14

2.28

16

4.0

0.72

1.82

3.64

18

6.4

1.16

2.90

5.82

20

10.2

1.86

4.64

9.28

22

16.1

2.92

7.32

14.64

AWG

Rating

m

Ω

/m

Temperature Offset in

°C (Meter)

a

100 m

200 m

300 m

14

8.3

0.44

0.86

1.30

16

13.2

0.68

1.38

2.06

18

21.0

1.10

2.18

3.28

20

33.5

1.74

3.48

5.22

22

52.8

2.74

5.48

8.22

M24304

TEMPERATURE (DEGREES)

RESISTANCE (OHMS)

1403

1317

1231

1145

1059

973

20

40

60

80 100 120 140 160 180 200 220

0

10 20 30 40 50 60 70 80 90 100

°F

°C

0

-20

-40

120

110

250

-40

-20 -10

-30

1489

887

801

1097 ± 0.08 OHMS

AT 77°F (25°C)

POSITIVE TEMPERATURE COEFFICIENT (PTC) OF 2.1 OHMS PER °F

1

1

MOD1 40%

MOD2 60%

DI ON

HOME

RELAYS 1 2

ON

SENSORS

SENSOR A

78

SENSOR B

84

MENU AREA

home

menu

F

o

F

o

DATA AREA

LOCK ICON

6 BUTTON KEYPAD

M24563

Содержание T775U Series

Страница 39: ...T775U SERIES 2000 CONTROLLER 39 62 0255 07 ...