35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

63-2209—8

6

Fig. 4. Determining direction damper

shaft rotates when opening.

Manual Operation (Declutch)

CAUTION

Product Damage Hazard.

Do not use manual declutch without supporting

the load.

Support actuator load independently immediately

before and during use of manual declutch lever.

Manual declutch capability is available on some actuators.

Use the manual declutch lever to manually adjust the actuator

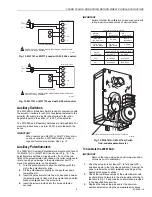

setting. Fig. 5 shows the location of the manual declutch lever.

To operate, push the lever in the direction of the arrow on the

lever cover.

Fig. 5. Location of manual declutch lever.

Installation

After determining the direction of the shaft rotation (cw or

ccw), install the device. For valve linkage mounting, refer to

the instructions shipped with the linkage. For damper

mounting, proceed as follows:

1.

Place the actuator onto the damper shaft.

CAUTION

Equipment Damage Hazard.

Improper range stop selection can damage

light-duty dampers.

Be sure to select the proper range stop.

2.

If the angle of the damper opening is either 45° or 60°,

close the actuator using the manual declutch:

a. Disengage the hub using the declutch lever; see

Manual Operation (Declutch) section.

b. Rotate the hub until the actuator gear train passes

the proper 45° or 60° setting. (Do not insert the pin

until after the actuator passes this point.)

c. Release the declutch lever.

NOTE: Dampers with 90° stroke do not require the

range stop pin.

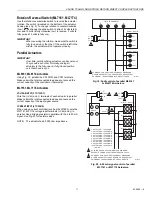

3.

Insert the range stop pin into the appropriate (cw or

ccw) 45° or 60° slot. The range stop pin clips into its

final position only after the pin passes through both

actuator plates (see Fig. 7). The range stop pin should

snap into position and not be removable manually

IMPORTANT

Do not fully tighten the mounting screw; the actuator

must be allowed to float.

4.

With the actuator placed in its final position, fix the

mounting tab in position with a 1/4 in. screw or pin. See

5.

Position the damper in the open position and securely

tighten the Allen screws into the damper shaft.

Fig. 6. Proper actuator mounting to prevent rotation.

AIR

FLOW

AIR

FLOW

CW TO OPEN, CCW TO CLOSE

CCW TO OPEN, CW TO CLOSE

M2067BB

TYPE A DAMPER

TYPE B DAMPER

M10076B

MANUAL

DECLUTCH

LEVER

ROTATION

REVERSAL SWITCH

60

60

M20884

1MM

(1/32 IN.)

1MM (1/32 IN.)