35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

7

63-2209—8

Fig. 7. Range stop pin properly inserted.

Fig. 8. Lifting range stop pin out of its slot.

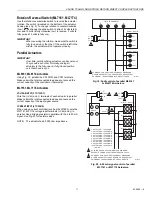

Minimum Position Setscrew

Certain ML6161, ML6174 and all ML7161, ML7174 models

are equipped with two tapped holes located in the plastic

housing at the top of the actuator. These holes can be used

with the minimum position setscrew and locknut inside the

4074ENJ Bag Assembly (see Fig. 9). The setscrew provides

for a 0° to 30° minimum position adjustment.

NOTE: Before starting operation, note that the 1/4 in.

minimum position setscrew limits closing motion,

while the range stop pin limits opening motion.

1.

Determine the direction of the desired closing rotation.

2.

Move the actuator to the position fully opposite the

desired closing rotation (if cw closing rotation is desired,

move the actuator to the full ccw position).

3.

Determine the correct hole for the setscrew using Fig. 9

and the results of step 1.

CAUTION

Equipment Damage Hazard.

Improper hub positioning or hole selection can

permanently damage the device.

Avoid backdriving the actuator with the setscrew.

4.

Remove the red cap from the desired hole. Leave the

other cap in position. The caps ensure that dust and

other impurities do not enter the gear train through

unused holes.

5.

Thread the locknut fully onto the 1/4 in. setscrew.

6.

Insert the setscrew into the desired hole, turning

clockwise until resistance is encountered or the locknut

contacts the housing.

7.

If resistance is met before the setscrew is fully inserted,

stop and review the initial setup procedures as detailed

in steps 1 through 3.

8.

Determine the angle of minimum position required for

the application. With the setscrew fully inserted, the

minimum position is 30°. With the setscrew fully out, the

minimum position is 0°.

9.

Using the conversion of approximately 1.7 angular

degrees per turn of the setscrew, back the screw out of

the housing and stop slightly short of the calculated

position. This allows the setscrew to be set accurately

while taking air flow measurements.

IMPORTANT

After initiating step 10, the setscrew cannot be turned

into the housing without returning the actuator to the

fully open position (as determined in step 1). The

actuator follows the setscrew without damaging the

housing only when backed out of the housing (turned

ccw).

10.

Rotate the actuator to minimum position using the

manual declutch; see Manual Operation (Declutch)

section.

11.

With the actuator at minimum position, adjust the

position more accurately using air flow measurements.

NOTES:

1.

After each adjustment, ensure the actuator is

completely stopped before proceeding with the

next adjustment.

2.

To reduce the minimum position, turn out the set-

screw (ccw). The actuator then drives toward the

closed position.

3.

Turning the setscrew in (cw) damages the

actuator housing.

4.

If the device is too far closed, return to step 1.

12.

When proper air flow is achieved, loosen the locknut

from the setscrew until it contacts the actuator housing,

then turn it an additional 1/8 turn to lock the setscrew in

place.

60

45

45

60

CW

CCW

COM

RANGE STOP PIN

ACTUATOR PLATES

M10246A

SCREWDRIVER

M2065