BA_PH_245-20_EN_15-22.docx

61

18.5

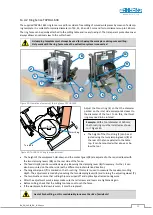

Change and Tighten the Drive Belt

Switch off the machine during belt replacement and tightening and secure it against

unintentional restarting! Lock the main switch with a padlock!

The drive belt should be replaced in the event of excessive wear, frayed flanks, traces of oil, porosity or if cross-

sectional fractures are present.

Figure 62: Tightening drive belt

Change drive belt and tighten the new one

1.

Open the front service door.

2.

Swivel the lever (

E

) all the way in the direction of the

arrow to release the belt.

Important:

If the worn out

belt has already been retightened, additionally

loosen the counter nut (

K

) and reduce the belt ten-

sion by turning the adjusting screw (

E

) anticlockwise

. This is necessary to prevent the new belt from

overstretching.

3.

Remove the old belt and fit a new one (for speed set-

ting, refer to chapter

4.

Important:

Before tightening, make sure that the

belt is correctly positioned in the speed fork again.

5.

The correct belt tension for the new belt is set using the adjusting screw (

S

). To do this, approach it step by

step by first tightening the adjusting screw (

S

) only slightly in clockwise direction, swinging the lever (

E

) back

again and then checking the belt tension. Repeat this procedure until the correct belt tension (according to

section

18.5.1) is achieved.

6.

Then tighten the lock nut (

K

) again and swivel the lever (

E

) back to its original position.

Tighten drive belt

1.

Swivel the lever (

E

) all the way in the direction of the arrow to make it easier to tighten the belt.

2.

Loosen the counter nut (

K

) and set the correct belt tension with the adjusting screw (

S

).

To do this, proceed as described above in step 5.

3.

Then tighten the lock nut (

K

) again and swivel the lever (

E

) back to its original position.

18.5.1

Checking the Drive Belt Tension

The correct pretension of the drive belt can be checked

as follows:

4.

Press the drive belt (in the middle between the two

belt pulleys) from above with a strong thumb pres-

sure (approx. 2 kg).

5.

With correct pretension, the belt must only be able to

be pushed downwards (

X

) by max. 5 mm.

6.

If a new belt is installed, it must only be possible to

push it downwards (

X

) by max. 2 mm.

Figure 63: Checking the belt tension

Too low belt tension leads to increased wear or failure of the belt.

Excessive belt tension can cause bearing damage to the drive axes.

K

S

E

X