--- 15 ---

Tool holder

Slip clutch mechanism

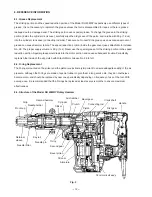

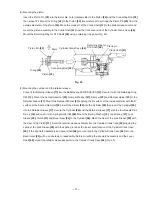

The slip clutch mechanism is described below with reference to Fig. 8. The bevel pinion and the gear holder

are coupled together by the key and press-fitting. Spring (C) and needle pins are housed in elongated grooves

of the gear holder. The needle pin is pressed against the inner face of the second gear by spring (C) to allow

idle rotation of the second gear relative to the gear holder. When an excess torque is exerted on the bevel

pinion shaft, the needle pin is raised upon the projection of the second gear against the load of spring (C) to

allow idle rotation of the second gear. With the arrangement, the clutch slips when an excessive torque is

applied to the working tool as when the drill bit contacts steel bar/wire in the concrete, protecting the operator

from unexpected motion of the side handle.

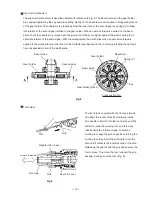

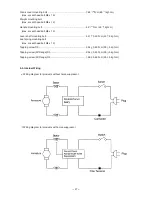

The tool inlet is covered with the front cap (made

of rubber) to prevent chips from entering inside.

Two needle rollers fall into the round groove of the

drill bit to retain the working tool, and three key

rails transmit the rotation torque. To attach a

working tool, align the groove positions turning the

working tool, then insert the working tool into the

hole until it contacts the innermost end of the hole.

Releasing the grip reverts the grip and secures the

tool in place. To remove the tool, fully pull the grip

backward and pull out the tool. (Fig. 9)

Tool

Grip

Needle roller (2 pcs.)

Key rail (3 pcs.)

Front cap

Grip

Forward Backward

Fig. 9

Fig. 8

Needle pin

Gear holder

Bevel pinion

Spring (C)

Second gear

Bevel pinion

Gear holder

Gear holder groove

Key

Cross section A-A

Содержание DH 40MRY

Страница 39: ......