NOTE

: Use a jet of water to eliminate any remaining dirt, and use a spatula or a brush with soft

bristles to eliminate any dirt that is particularly hard to remove.

10.

Wait for the vacuum motor's filter to dry, if necessary, and then place it back on its support.

ATTENTION

: Wait for the filter to dry completely before using it again, or else use a spare.

11.

Remove the vacuum motor's duct filter from its support (5) (

Fig.5

).

12.

Clean the vacuum motor's duct filter under a jet of water (5).

NOTE

: Use a spatula to eliminate any dirt that is particularly difficult to remove.

13.

Dry the vacuum motor's duct filter with a dry cloth (5) and place it back on its support.

14.

Clean the lower part of the vacuum cover with a damp cloth, and carefully clean the filter gaskets

(

Fig.6

).

15. Grip the handle (1) and turn the recovery tank's cover to its working position.

5. CLEANING THE RECOVERY TANK

To clean the recovery tank (without the optional tank cleaning kit), proceed as follows:

1. Perform the procedure for emptying the recovery tank (see the section titled “

EMPTYING THE

RECOVERY TANK

”).

2. Make sure the machine has been secured (see the section titled “

SECURING THE MACHINE

”).

CAUTION

: users are advised to always wear protective gloves, to avoid the risk of serious injury

to hands.

3. Once the recovery tank has been emptied, grip the handle (1) and raise the recovery tank's lid to

its maintenance position (

Fig.1

).

4. Rinse the inside of the recovery tank with a jet of water. If necessary, use a spatula to remove any

sludge that may have accumulated at the bottom of the tank.

ATTENTION

: Be sure to also clean the electro-mechanical floats (2) present inside the tank

(

Fig.2

).

5. Repeat the operations in reverse order to reassemble all the parts.

To clean the recovery tank (with the optional tank cleaning kit), proceed as follows:

1. Take the machine to the maintenance area.

2. Raise the brush head body by turning the brush head control lever (1) on the rear part of the steering

column (

Fig.1

).

3. Raise the squeegee body by turning the squeegee control lever (2) on the rear part of the steering

column (

Fig.2

).

CAUTION

: users are advised to always wear protective gloves, to avoid the risk of serious injury

to hands.

4. Detach the recovery tank drainage tube (on the back of the machine) from the retainers holding it

in place (

Fig.3

).

5. Bend the end of the drainage tube in order to create a choke and prevent the content from coming

out (

Fig.4

), then position the tube on the discharge surface, unscrew the cap, and gradually release

the tube.

NOTE

: the place designated for this operation must comply with current environmental

protection regulations.

6. Once the recovery tank has been emptied, grip the handle (3) and raise the recovery tank lid to its

maintenance position (

Fig.5

).

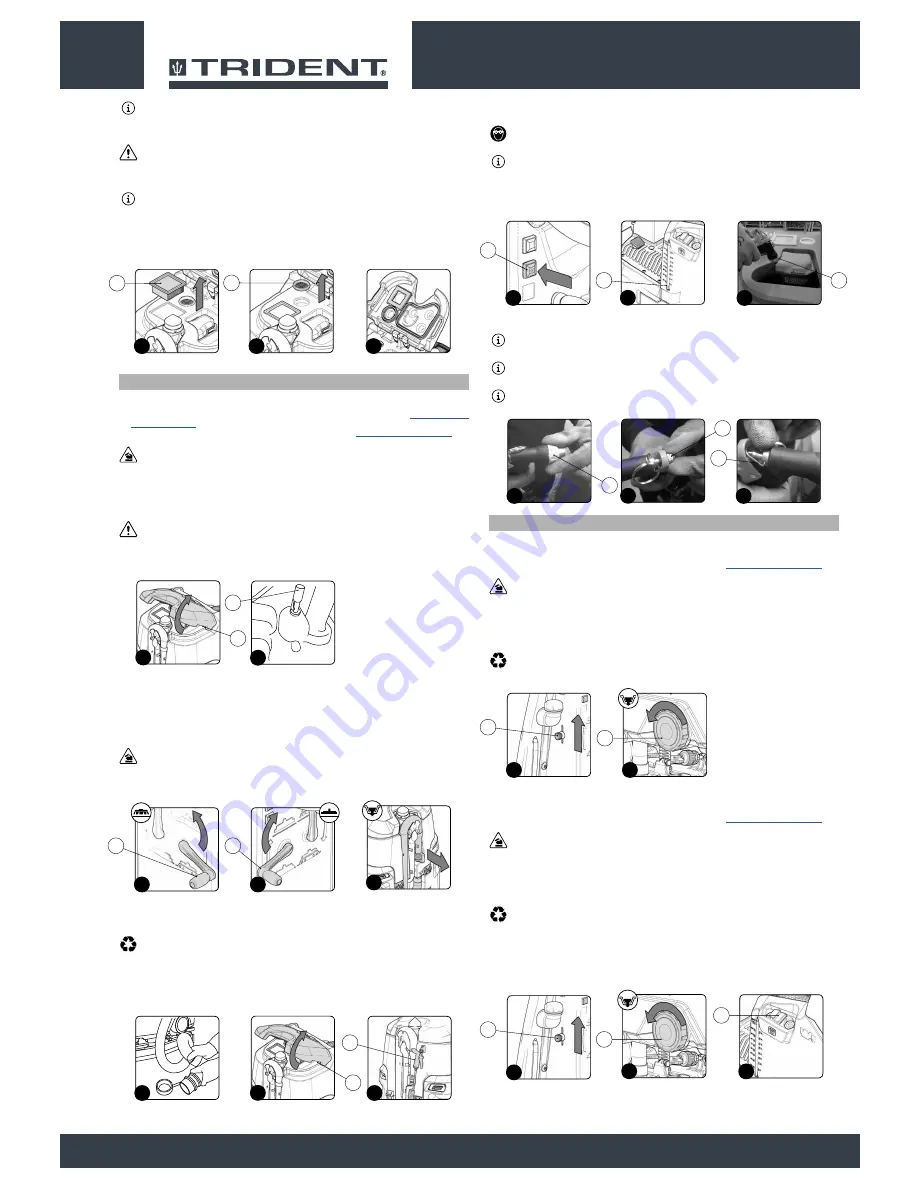

7. Release the tank cleaning accessory (4) (at the back of the machine) from the retainers (

Fig.6

).

8. Activate the optional tank cleaning kit ON/OFF pump by pressing the button (5) on the front left part

of the machine (

Fig.7

).

CAUTION

: when using the optional tank cleaning kit, you are advised to always wear goggles to

avoid any risk of serious injury to your eyes.

NOTE

: before activating the optional tank cleaning kit, check the level indicator (6) to see how

much solution there is in the recovery tank (

Fig.8

).

9. Activate the solution jet by pressing the lever (7) in the tank cleaning accessory (4) (

Fig.9

). Make

sure the jet is pointing into the tank before pressing the lever.

10.

Clean the inside of the tank with the jet, replacing all the parts when you have finished.

NOTE

: to adjust the jet from the

tank cleaning accessory (4), turn the knob (8) on the accessory

itself

(

Fig.10

).

NOTE

: to adjust the intensity of the jet from the

tank cleaning accessory (4), turn the knob (9) on

the accessory itself

(

Fig.11

).

NOTE

: to stop the solution jet,

use the lever (10) on the accessory itself

(

Fig.12

).

6. EMPTYING THE SOLUTION TANK

Proceed as follows to empty the solution tank:

1. Take the machine to the maintenance area.

2. Make sure the machine has been secured (see the section titled “

SECURING THE MACHINE

”).

CAUTION

: users are advised to always wear protective gloves, to avoid the risk of serious injury

to hands.

1.

Open the tap's output flow to maximum, and shift the knob on the left hand side of the steering

column (1) (

Fig.1

) upward.

2. Unscrew the cap (2) for the solution tank dumping system (

Fig.2

); the cap is located at the rear of

the machine.

NOTE

: the place designated for this operation must comply with current environmental

protection regulations.

Proceed as follows to clean the solution tank:

1. Take the machine to the maintenance area.

2. Make sure the machine has been secured (see the section titled “

SECURING THE MACHINE

”).

CAUTION

: users are advised to always wear protective gloves, to avoid the risk of serious injury

to hands.

1.

Open the tap's output flow to maximum, and shift the knob on the left hand side of the steering

column (1) (

Fig.1

) upward.

2. Unscrew the cap (2) for the solution tank dumping system (

Fig.2

); the cap is located at the rear of

the machine.

NOTE

: the place designated for this operation must comply with current environmental

protection regulations.

3. Remove the cap/measuring device (3) (

Fig.3

), located on the left-hand side of the machine.

4. Rinse the inside of the solution tank with a jet of water

5. With the solution tank empty, repeat the operations in the reverse order to reassemble all the parts.

20

4

4

6

5

5

3

1

2

1

2

1

2

1

2

4

6

5

3

4

7

9

8

10

12

11

2

1

1

1

1

2

2

3

2

3

5

8

9

10

6

7

Содержание TRIDENT R30SC

Страница 1: ...Scrubbing machine Use and Maintenance manual Original instructions DOC 10075358 Ver AA 11 2017 ...

Страница 2: ......

Страница 24: ...NOTES 24 ...

Страница 25: ...NOTES 25 ...

Страница 26: ...NOTES 26 ...

Страница 27: ......

Страница 28: ...HILLYARD INDUSTRIES PO Box 909 St Joseph Missouri 64502 0909 U S A Telephone 816 233 1321 www hillyard com ...