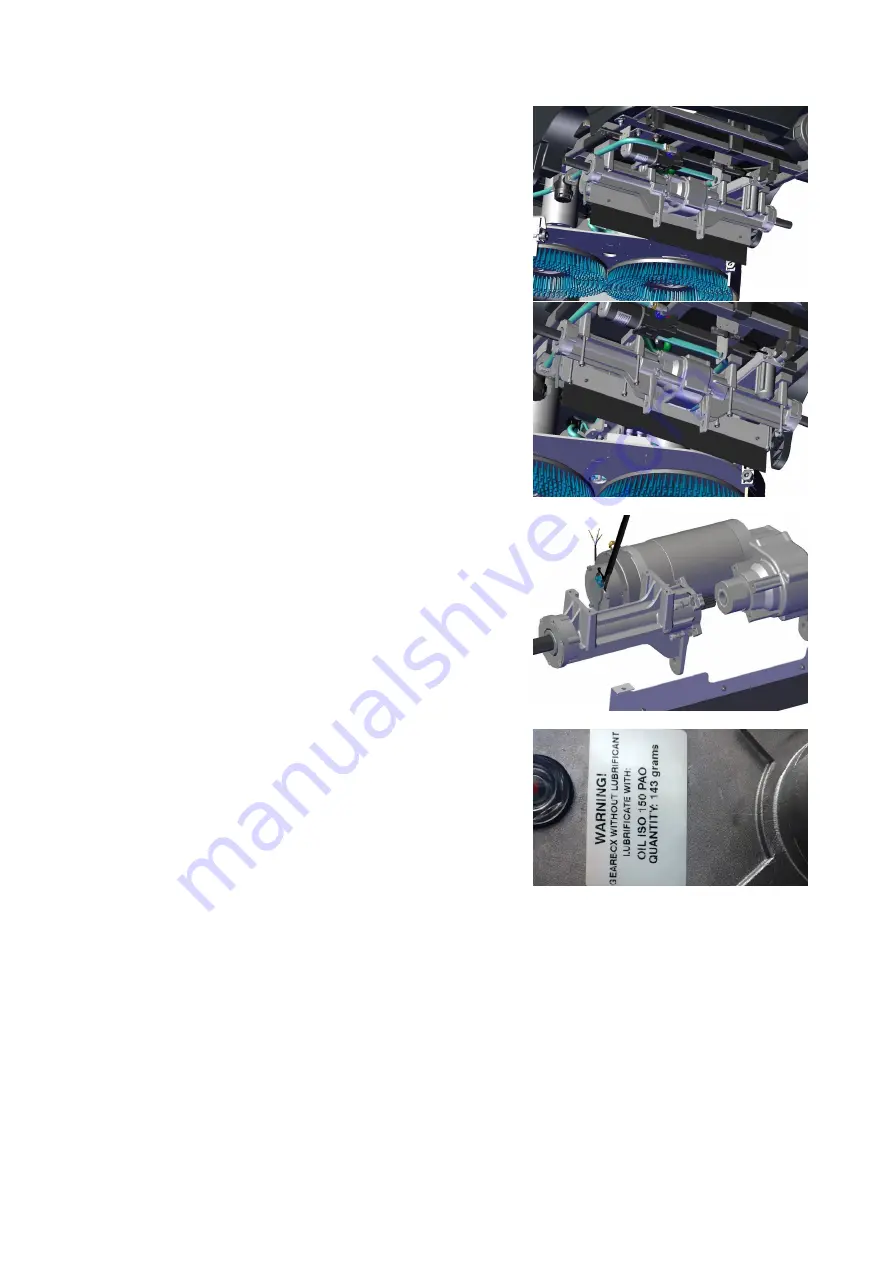

Disconnect the electrical wiring from the gearmotor, ie the two

power cables and the encoder cable (with molex connector).

Remove the screws securing the gearmotor and the splash guard

to the frame. Separate the screws that secure the splash guard as

they have a longer length than the other screws in the assembly.

Considering that when all eight screws have been removed, the

gearmotor will be free to fall to the ground.

Remove the spacers in the gearmotor just uninstalled.

In case of replacement, the gear is supplied empty, insert 143

grams (5 ounces) of oil type FLUIDO BIO ISO 150 PAO (EP) or

equivalent.

ATTENTION

: Do not exceed the required quan-

tity, although with the motor in a horizontal position you do not

see the level from the opening eye.

100

Содержание 108538

Страница 1: ...SERVICE MANUAL TRIDENT R30SC R28SC Version AA Date August 5 2019 Document Number 100x...

Страница 4: ...Part I Product Introduction 4...

Страница 10: ...1 6 Machine Dimensions 1 6 1 R30SC 10...

Страница 11: ...1 6 2 R28SC 11...

Страница 15: ...Part II Anomalies Resolution Guide 15...

Страница 24: ...Part III Functional Groups 24...

Страница 26: ...3 2 Location of Electrical Components 3 2 1 R30SC R28SC Plus 26...

Страница 28: ...3 2 3 R30SC Base 28...

Страница 64: ...4 6 Related electrical circuit 4 6 1 R30SC Base 64...

Страница 66: ...4 6 2 R30SC PLUS 66...

Страница 76: ...5 6 Related electrical circuit 5 6 1 R28SC PLUS 76...

Страница 80: ...Chapter 6 Vacuum Unit 6 1 Location on machine The vacuum unit is located in central rear position 80...

Страница 84: ...6 6 Related electrical circuit 6 6 1 R28SC Base 84...

Страница 86: ...6 6 2 R30SC R28SC PLUS 86...

Страница 94: ...7 5 Related electrical circuit 7 5 1 R30SC Base 94...

Страница 96: ...7 5 2 R30SC R28SC PLUS 96...

Страница 104: ...8 5 Related electrical circuit 8 5 1 R30SC Base 104...

Страница 106: ...8 5 2 R30SC R28SC PLUS 106...

Страница 112: ...Part IV Accessories and Add On 112...