27

Henrad CC FF

- Installation

35

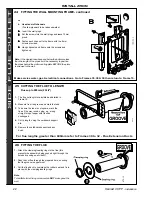

WATER CONNECTIONS

Refer to General Note, Frame 34, for guidance.

37 SAFETY VALVE DRAIN

The discharge pipe should be positioned so that the discharge of water or steam cannot create a hazard to

the occupants of the premises or damage to electrical components and wiring.

For top connections: reverse 22mm pipe.

Note.

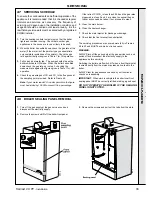

Do not subject any of the isolating valves to heat as the

seals may be damaged .

INSTALLATION

Bottom and Top connections

2. Remove the gas cock bracket complete with gas cock.

3. Screw connector into gas cock in the correct orientation.

4. Screw complete assembly back onto the mounting frame.

Extend a gas supply pipe of not less than 22mm O.D. copper or

3/4" BSP iron to the boiler.

A working gas pressure of 20mbar (8" w.g.) must be available at

the boiler inlet with the boiler firing at full DHW output.

INST

ALLA

TION

DHW CONNECTIONS

CH CONNECTIONS

For central heating loads greater than 60 000 BTUs the

flow and return circuits should be increase to 28mm pipe

diameter immediate;y upon leaving the boiler with the

fitting supplied.

For top connections:

use 15mm straight pipe and elbow (not supplied).

36

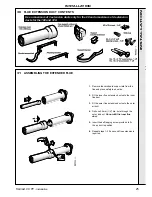

GAS CONNECTION

Refer to General Note, Frame 34, for guidance.

Bottom connection

1a. Solder the 1/2" connector and reducing coupling to the

preformed pipe provided

OR

Top connection

1b. Solder the 1/2" connector and reducing coupling to the

preformed pipe provided.

IMPORTANT. Ensure the gas supply pipework is adequate - see Table 5 page 8.