7

4 Installation

4.1 Environmental and Operating Conditions

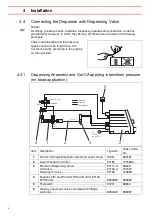

– Keep the pressure hose as short as possible. Short switch-on and switch-off times for

the dispensing valve are within reach.

– Keep product feed lines as short as possible. The shorter the feedline the smaller the

specific resistance and the lower the dispensing pressure can be.

– Avoid kinking of feed lines and pressure hoses.

– Typically, the pressure hose and product feedline should not be longer than 2 m.

– Do not use inflexible hoses and feed lines, so that unnecessary loads on the fittings

will be avoided.

– Keep all fittings tight.

– No direct sunlight; no UV light!

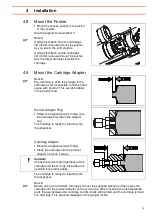

4.2 Space Requirements

4.3 Start Requirements

Warning!

Operate

the dispenser

only with closed and fixed shell

! Danger of pinching!.

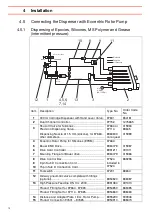

Operate cartridge dispenser when

– Cartridge is inserted,

– Shell is closed, clamp is fixed,

– Cylinder is in basic position (backward).

The factory settings of the pneumatic flow controls need no changing in the forward and

backward movements.

If they should be newly adjusted, adjust the screws of the outlet chokes so that:

– The forward and backward movements are performed smoothly.

– Each end position is reached in vibration-free manner.

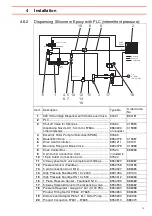

Pressure Input Limit

Caution!

Pressure input limit is max. 4 bar (58 PSI). Make sure that the limit is kept.

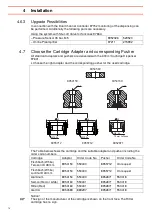

5

5

mm

2

.1

6

5

"

~960 mm

~ 38"

9 mm

0.354"

475 mm

18.7"

230 mm

9"

1

8

0

mm

7

.1

"

200 mm

7.9"

10 mm

0.4"

2

3

4

mm

9

.2

"

80 mm

3.15"

Содержание Loctite 854181

Страница 20: ...20 8 Annex 8 3 Declaration for Incorporation...

Страница 39: ...39 8 Anhang 8 2 Einbauerkl rung...