18

7 Troubleshooting

7.1 General

Type of malfunction

Possible causes

Correction

No product

– Pressure supply is switched

off.

– Too little pressure at the

cartridge cylinder.

•

Switch on pressure supply and/or

readjust pressure at the pressure

regulator for the cartridge cylinder.

Caution

!

Pay attention to the maximum

pressure of 4 bar (58 PSI).

Product runs out of the shell.

– Cartridge is not correctly

inserted.

– O-rings worn out

•

Insert cartridge correctly

according to section 4.4.

•

Replace O-rings, see section 5

Product runs out of the fittings.

– Fitting is not correctly screwed

in or tightened.

•

Screw in the fitting as far

as it will go.

LED indicator does not light.

– Connection is loose.

– Reed switch is not properly

located.

– Indicator is faulty.

•

Tighten plug connector.

•

See low level set-up instructions.

•

Replace sensor.

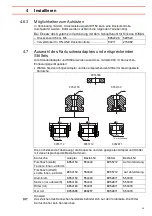

7.2 Systematic Elimination of Malfunctions

This section describes the systematic elimination of the malfunction.

Product does not come out of the dispensing valve

.

With the following procedure an easy search, finding and elimination of malfunctions in

the system can be achieved. Follow these instructions step by step to make sure to find

the reason for this malfunction and how to handle it.

In this procedure the point

check

has to be done several times.

It means the following steps:

Step 1

Switch on the cylinder.

Step 2

If necessary switch on the eccentric rotor pump.

Step 3

If necessary switch on the dispensing valve.

If the malfunction is cleared, product should come out of the checked part.

Procedure

Dispensing Valve

•

Check

– Product comes out of the dispensing nozzle.

Maybe, some particles were in the nozzle and you can continue dispensing.

•

Dispensing nozzle is clogged; change the nozzle or

•

Disconnect feedline at the dispensing valve.

•

Check

– Product comes out of the feedline.

•

Dispensing valve is clogged; change valve.

Eccentric rotor pump

•

Disconnect feedline at the product outlet of the eccentric rotor pump.

•

Check

– Product comes out of the eccentric rotor pump.

•

Feedline is clogged; change feedline or

•

Disconnect feedline at the product inlet of the eccentric rotor pump.

•

Check

– Product comes out of the feedline.

•

Eccentric rotor pump is clogged; change pump.

Содержание Loctite 854181

Страница 20: ...20 8 Annex 8 3 Declaration for Incorporation...

Страница 39: ...39 8 Anhang 8 2 Einbauerkl rung...