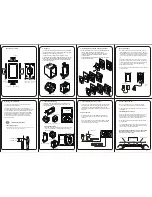

HPAK SYSTEM COMPONENTS OVERVIEW

1.6.3. Operation of Combo Valves

The combo valves are integrated check and ball valves, with temperature gauges. Cracking pressure (minimum fluid flow pressure)

of the check valves is 0.30 psi. The valves can be operated by turning the plastic handles clockwise, with note taken of the position

of the slots on the handles, indicating valve position as pictured in figures 1.6.3.-1 – 3 below. To ensure proper compression fitting

seals, clean and round copper tubing must be used. Use a counter wrench on the hex provided to fully torque compression nut

fittings. Bush up or down as necessary for proper flow rates.

1.6.1. Tempering Valve

Install a tempering valve to prevent scalding; the solar storage may reach 180°F. Some areas may require a rated Anti-Scald

valve.

For dual tank systems with a gas backup, install the tempering valve before the gas water heater and after installing the solar

storage tank, to avoid a service call for high limit fuse replacement. For dual tank systems with an electric tank, the tempering

valve may be installed before or after the tank. For instantaneous water heaters as backup, consult the manufacturer for the

recommended method of tempering or bypass of solar heated water into the heater.

1.6.2. System Overheat Protection and Operation of Pressure Relief Valve and Expansion Tank

The HPAK comes with a preinstalled pressure only relief valve, nonadjustable and pre-set at 150 psig. A 1/4“ barbed hose fitting is

supplied for routing relief fluid to a drain or retaining vessel.

In addition, the system comes with a pre-sized bladder type expansion tank. The acceptance volume of the expansion tank

should be large enough to store up to 17 – 20% of the total collector system fluid volume.

With these safety precautions, and high temperature Dyn-O-Flo HD propylene glycol, the system can stagnate for short periods.

If extended periods (2 weeks or more) are expected, install a Delta-T Pro with the proper vacation setting. Additionally, the

system should never have less than 1.5 gallons of storage for each square foot of collector surface area.

1.6.4. Operation of Filling Valve

The filling valve integrates three gate valves into one.

The green handles operate the inlet and outlet of the

valve, while the drain fitting on the side enables either

filling or system operation. Always fill the system in the

direction of the flow path.

If not using a Heliodyne filling station, hose adapters

are set into the HPAK foam to the right of the fill

valve.

16

14

15

61

7

17

Figure 1.6.4.-1: Drain Fitting Open

(Operation Position)

Figure 1.6.4.-2: Drain Fitting Closed

(Fluid Servicing)

Figure 1.6.3.-1: Ball Valves Open

(Operation Position)

Figure 1.6.3.-2: Check Valves Open

(Fluid Servicing)

Figure 1.6.3.-3: Ball Valves Closed

(HPAK Servicing)

Item

Numbers