79

HEIDENHAIN TNC 426 B, TNC 430

Tool radius compensation

The NC block for programming a tool movement contains:

■

RL or RR for compensation in the tool radius

■

R+ or R– for radius compensation in single-axis movements

■

R0 if no radius compensation is required

Radius compensation becomes effective as soon as a tool is called

and is moved in the working plane with RL or RR.

The TNC cancels radius compensation if you:

■

program a positioning block with R0

■

depart the contour with the DEP function

■

program a PGM CALL

■

select a new program with PGM MGT

For tool radius compensation, the TNC takes the delta values from

both the TOOL CALL block and the tool table into account:

Compensation value = R + DR

TOOL CALL

+ DR

TAB

, where

R

is the tool radius R from the TOOL DEF block or

tool table

DR

TOOL CALL

is the oversize for radius DR in the TOOL CALL block

(not taken into account by the position display)

DR

TAB

is the oversize for radius DR in the tool table

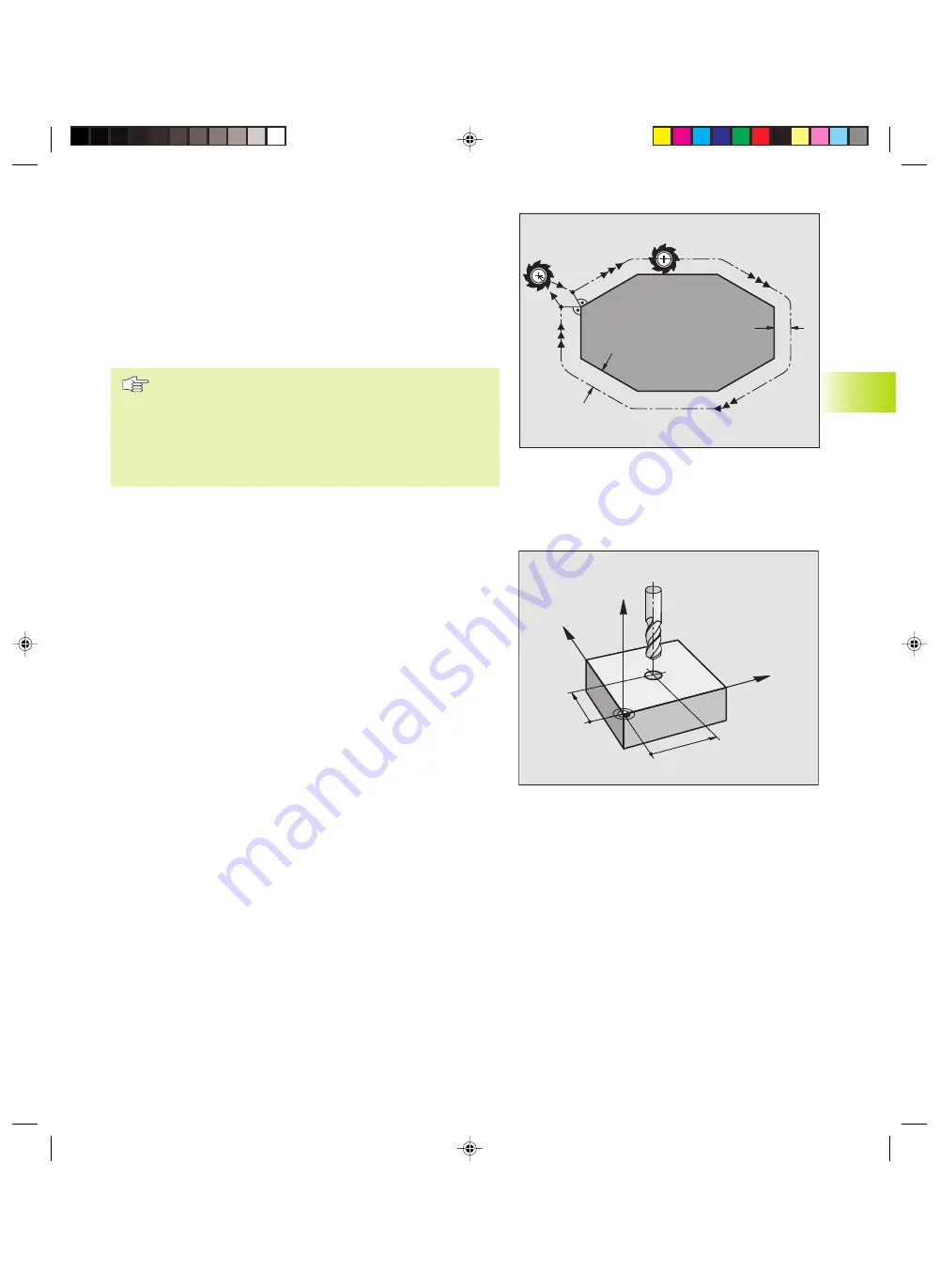

Tool movements without radius compensation: R0

The tool center moves in the working plane to the programmed

path or coordinates.

Applications: Drilling and boring, pre-positioning

(see figure at right)

Tool movements with radius compensation: RR and RL

RR

The tool moves to the right of the programmed contour

RL

The tool moves to the left of the programmed contour

The tool center moves along the contour at a distance equal to the

radius. “Right” or “left” are to be understood as based on the

direction of tool movement along the workpiece contour (see

illustrations on the next page).

5.3 T

ool Compensation

R

R

R0

RL

Y

X

Z

X

Y

Fkap5.pm6

30.06.2006, 07:03

79

www.EngineeringBooksPdf.com

Содержание TNC 426 B

Страница 3: ...BAUSKLA PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Страница 4: ...BAUSKLA PM6 30 06 2006 07 03 3 www EngineeringBooksPdf com ...

Страница 6: ...CINHALT PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Страница 16: ...CINHALT PM6 30 06 2006 07 03 12 www EngineeringBooksPdf com ...

Страница 17: ...Introduction 1 Dkap1 pm6 30 06 2006 07 03 1 www EngineeringBooksPdf com ...

Страница 29: ...Manual Operation and Setup 2 Dkap2_3 pm6 30 06 2006 07 03 13 www EngineeringBooksPdf com ...

Страница 39: ...Positioning with Manual Data Input MDI 3 Dkap2_3 pm6 30 06 2006 07 03 23 www EngineeringBooksPdf com ...

Страница 83: ...Programming Tools 5 Fkap5 pm6 30 06 2006 07 03 67 www EngineeringBooksPdf com ...

Страница 106: ...Fkap5 pm6 30 06 2006 07 03 90 www EngineeringBooksPdf com ...

Страница 107: ...Programming Programming Contours 6 Gkap6 pm6 30 06 2006 07 04 91 www EngineeringBooksPdf com ...

Страница 148: ...Programming Miscellaneous functions 7 Hkap7 pm6 30 06 2006 07 03 133 www EngineeringBooksPdf com ...

Страница 165: ...Hkap7 pm6 30 06 2006 07 03 150 www EngineeringBooksPdf com ...

Страница 166: ...Programming Cycles 8 kkap8 pm6 30 06 2006 07 03 151 www EngineeringBooksPdf com ...

Страница 253: ...kkap8 pm6 30 06 2006 07 04 238 www EngineeringBooksPdf com ...

Страница 254: ...Programming Subprograms and Program Section Repeats 9 LKAP9 PM6 30 06 2006 07 04 239 www EngineeringBooksPdf com ...

Страница 265: ...LKAP9 PM6 30 06 2006 07 04 250 www EngineeringBooksPdf com ...

Страница 266: ...Programming Q Parameters 10 MKAP10 PM6 30 06 2006 07 04 251 www EngineeringBooksPdf com ...

Страница 297: ...MKAP10 PM6 30 06 2006 07 04 282 www EngineeringBooksPdf com ...

Страница 298: ...Test Run and Program Run 11 NKAP11 PM6 30 06 2006 07 04 283 www EngineeringBooksPdf com ...

Страница 312: ...MOD Functions 12 Okap12 pm6 30 06 2006 07 04 297 www EngineeringBooksPdf com ...

Страница 332: ...Tables and Overviews 13 Pkap13 pm6 30 06 2006 07 04 317 www EngineeringBooksPdf com ...